Block boiler plants (BKU)

Price from: $ 1

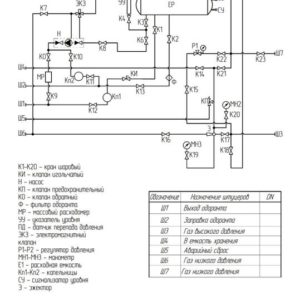

The BKU block boiler plant is an individual product designed for heating industrial, administrative, cultural and domestic facilities. The main and unconditional advantage of BKU over centralized heat supply is the short length of communications and the ability to respond quickly to a changed temperature situation, which can significantly reduce losses and energy costs. BKU are manufactured of various capacities and modifications depending on the type of fuel used: natural gas, fuel oil, diesel fuel, solid fuel, combined fuel (gas-fuel oil, gas-diesel fuel). ) and a moderately cold climate (UHL, NF), as well as in areas with a cold climate (HL, F). The climatic version of the BKU is chosen depending on the construction area, in accordance with the requirements of GOST 15150-69. BKU can be operated in areas with seismicity up to 9 points inclusive according to SNiP RK 2.03-30-2006. The design snow load (200 kgf / m2) meets the requirements of the V territorial region, and the wind load (85 kgf / m2) corresponds to the VII territorial region according to SNiP 2.01.07-85. and commissioning of the BKU; no large capital costs for the construction of a room for a boiler room; significantly reduces the costs of heat supply and operation of engineering networks; maximum proximity of the BKU to the heat supply facility; simple and convenient solution to the issue of decentralizing heat supply. residential and industrial buildings with complex infrastructure, and the use of district heating is impossible, it is advisable to build a boiler house on the roof. I am from the central control room, as well as to ensure the protection of boiler equipment in emergency situations. The automated control system of the ACS TP BKU is made on the element base of Siemens and performs the following functions: control of equipment operation and control of technological parameters of the boiler room; weather-dependent control of the heating circuit; control of DHW circuits; cascade control of boiler power; output of information on the state of equipment and technological process to the operator panel; control of the gas valve of the boiler room; alarm of gas contamination (for natural and carbon monoxide); transmission of technological parameters and warning and alarm signals to the control room through the channels of a dedicated line, telephone line, GSM, etc. The control automation also includes an electronic unit with a set of temperature sensors, which serves to adjust the temperature of the coolant depending on the outside temperature.

Send Me Quotation

The function is avialable for logged in users only