PBM-PP-90/250 magnetic drum separator

Price from: $ 1

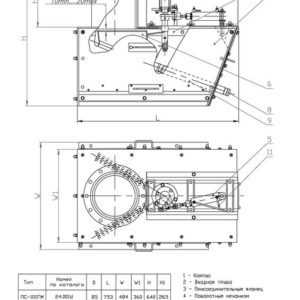

The magnetic drum separator with a semi-countercurrent bath PBM-PP-90/250 is designed for enrichment by the wet separation method of highly magnetic ores and materials up to 1 mm in size with separation into two products: magnetic and non-magnetic. They are used to equip concentrating plants, ferrous metallurgy enterprises. The design of the PBM-PP-90/250 separators allows you to change the position of the magnetic systems, creating an optimal operating mode. A distinctive feature of the PBM-PP-90/250 separators is their increased reliability, ease of operation and maintenance. The drums of the PBM-PP-90/250 separators are equipped with wires in the form of gear motors of our own production, both for internal and external drives, while ensuring their trouble-free operation during the cycle between two major overhauls (at least 18,000 hours). Separators with internal and external drives are interchangeable in terms of technological parameters, overall and installation dimensions. Shells and end caps of drums, as well as boxes, baths, discharge chutes, boxes receivers, feed pipes, discharge tail chutes are covered with wear-resistant polyurethane coatings, which ensure the service life of not less than 18000 hours (cycle between overhauls). Also, at the request of consumers, the metal structure of the separator can be supplied with painting of the outer surfaces with zinc-filled polyurethane anticorrosive coatings with a service life of at least 6 years. separators. Equipment and spare parts for dry magnetic separation and wet magnetic separation. Those. specifications Indicator name Indicator Productivity for the initial solid material, t / h 105-160 Magnetic induction on the drum surface, T not less than 0.160 Drum diameter, mm 900 Drum length, mm 2490 Electric drive power, kW, not more than 4 Power supply size, mm 0-1 Overall dimensions, mm 3300х2100х4000 drums

Send Me Quotation

The function is avialable for logged in users only