SUBMERSIBLE ELECTRIC CENTRIFUGAL PUMPS

Price from: $ 1

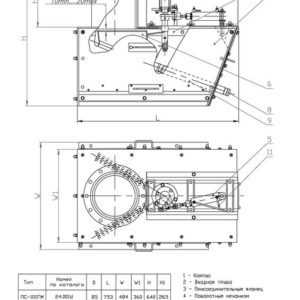

Applications • wells with a high content of solids; • wells with a high gas content at the pump intake; • wells with increased corrosiveness of the formation fluid; • wells with a high temperature of the formation fluid; • wells after hydraulic fracturing; • wells after drilling, incl. h. horizontal, sidetracked, exploration and deviated wells; • traditional wells. The RIMERA-ALNAS company produces standard and high-speed pumps with floating stages, pumps of compression or batch assembly of stages with a productivity from 10 to 1550 m3 / day with a speed control range of 2400 – 6000 rpm: • Pumps with stages floating type: impellers are located on the shaft inside the guide vanes and have the ability to move axially by the amount of permissible clearance. axial loads of impellers are transmitted to the pump casing, axial shaft loads are transferred to the axial support of the tread shaft. • Pumps with package assembly of stages: impellers are located on the shaft in several packages and are fixed on the shaft from axial movement. The axial loads of the impeller package are transferred to the angular contact bearings of the pump, the axial loads of the shaft – to the hydrodynamic axial support of the hydraulic protection shaft. wheels are transferred to the hydrodynamic axial support of the hydraulic protection shaft. Those. Specifications Features and Benefits: • Pumps of corrosion-resistant, corrosion-wear-resistant and high-corrosion-wear-corrosion-resistant versions with stage material hardness up to 240 HB • Optimal arrangement of radial bearings along the entire length of the pump section. Radial bearings in pumps with a capacity of more than 250 m3 / day at 50 Hz are built into the working stage; • pumps with floating stages, with batch and compression stage assemblies; • simplified installation of compression-assembled pumps. The contact of the shafts of the pump sections is achieved by an adjusting bolt, which is secured by a coupling against loosening. The bolt adjustment procedure during installation is carried out with a special device without the use of measuring tools; • Corrosion-resistant design of the pump casing, corrosion-resistant coating of the casing or stainless steel casing; • Shafts in the sections are made of high-strength stainless steel or high-alloyed alloys such as Monel or ALLOY. • involute intersectional connection of shafts.

Send Me Quotation

The function is avialable for logged in users only

Specification

| Product value | 0,50 м3 |

| Product length | 1 м |

| Product width | 1 м |

| Product height | 0,50 м |

Reviews

There are no reviews yet.