Washing unit Frictional (with the possibility of heating water)

Price from: $ 1

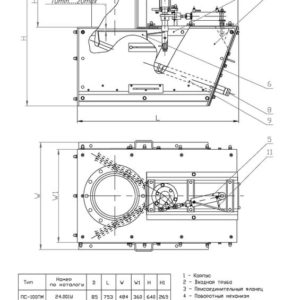

The water can be used both hot and cold. Detergents can also be used for cleaning. The main working bodies of the unit are three centrifugal blowers with which it is equipped. Each centrifugal blower is actually a specially designed friction centrifuge. During the operation of centrifugal blowers, a number of physical processes take place in them, which simultaneously ensure the separation and removal of contaminants from the material being processed. At the inlet to the blowers, a significant uncharged pressure is created, which allows the material to be “sucked in” into its working area. Together with the material, working water is supplied to the inlet of the blower, which washes away impurities, coagulates them and gives them additional mass. The impeller of the supercharger and the walls of its perforated shell create the effect of friction and, in fact, "wipe" the dirt from the material. The high speed of rotation of the impeller creates significant centrifugal forces, due to which "rubbed off" and acquired an additional mass of pollution fly out together with water through the shell perforation, and the material, because has a particle size larger than the perforation hole, is transferred to the next centrifugal blower. To improve the efficiency of the equipment, its manufacturability, reduce the periods of stoppages for maintenance, the unit can be equipped with various additional equipment, such as a storage tank with the function of separating contaminants by density, an autonomous water purification system from mechanical and dissolved contaminants, and others. (The picture shows the friction washer unit in the maximum configuration. The final configuration of the supplied unit corresponds to the list of options selected by the Customer specified in the item "Optional equipment"). The unit can operate both in a flow-through mode (working water washes away impurities and is discharged outside the unit), and in a cyclic mode (working water washes away impurities and drains into a tank, from which it is again pumped into the unit). The flow-through mode is most useful when cleaning contaminants such as cement, sugar, flour, etc., which quickly turn water into a solution, syrup or paste and deprive it of its detergency. The use of a cyclic mode of operation of the Unit can be used when washing mechanical impurities or when equipping the unit with a water purification system. The material supplied to the unit must be pre-crushed. The particle size of film and filamentary materials should be no more than 40 mm on the largest side, and solid – no more than 25 mm. Both those and other particles must be at least 5-7 mm. Processing of PET waste, film and filamentary, solid thin-walled into secondary raw materials

Send Me Quotation

The function is avialable for logged in users only

Specification

| Product value | 1 м3 |

| Product length | 1 500 мм |

| Product width | 1 200 мм |

| Product height | 2 200 мм |

Reviews

There are no reviews yet.