Delivery of crumb rubber up to 500 tons monthly

Price from: $ 1

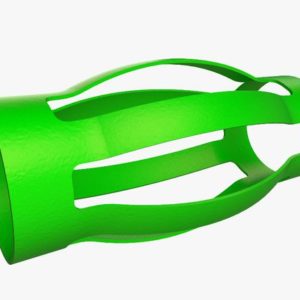

No. Specification US Mesh inches Microns 1 30 0.0232 595 182.62 40 0.0165 400 2303 60 0.0098 250 349.24 80 0.0070 177 603.25 100 0.0059 149 1000 • Container – polypropylene bags. Fields of application of crumb rubber Crumb rubber is the main product of used tires recycling and is in constant demand on the world market, exceeding supply. This is the most wear-resistant rubber raw material, has wide application: 1. Production of EcoStep safety rubber tiles. The rubber tile, made from the most wear-resistant rubber raw materials, has wear resistance, strength, shock-absorbing, shock-absorbing and orthopedic properties. The specific gravity of crumb rubber in the production of rubber tiles and paving stones is more than 80%, therefore, the quality and durability of rubber tiles directly depends on the quality and properties of crumb rubber. 2. Floor coverings for sports fields and facilities. Rubber crumb and polymer binders coatings for sports grounds, basketball, volleyball, badminton courts. Anti-slip and safe entry cover. In these types of coatings, crumb rubber is also used. The addition of crumb rubber obtained from the processing of tires makes the coatings more wear-resistant and practical, they have better plasticity, and they are durable. 3. Fillers for sports equipment. Crumb rubber is used as a filler for bags and punching bags. 4. Football fields with artificial turf are covered with rubber crumb from 1.0 to 2.5 mm. For example, filling a football field at a stadium requires up to 100 tons of crumbs of the same fraction. 5. Covering building material. This is a roofing material in the form of combining bitumen with polyurethane, from above it is poured with a composition of tiokol with the addition of fine refined rubber crumb. To carry out the whole range of works on the application of coatings on the roofs of residential and industrial buildings, various materials with the addition of crumb rubber are recommended for use: slopes (up to 90% of crumb rubber), sealing of seams (up to 50% of crumb rubber), sealing of joints (up to 70% of rubber crumb), directly coating (up to 50% of rubber crumb). The final, most resistant layer with the use of crumb rubber protects all underlying layers. 6. Structural fiber concrete. Metal and textile cord in a certain proportion is mixed with rubber crumb and added up to 50% to the dry cement-sand mixture. It is used for deep casting of foundations. Floor coverings and ladders, in places of heavy traffic. Polyurethane is mixed with 50% fine (fraction less than 3 mm) refined rubber crumb. It is used for both indoor and outdoor areas. Due to its properties, fiber-reinforced concrete is used in regions with harsh climatic conditions, including permafrost regions. 7. Finishing building material. Thiokol (polysulfide) system as standard material and chips (less than 1 mm) form a durable covering material, using both as a decoration and as a decorative wall material. 8. For road surface. Crumb rubber is used in the latest generation of road surfaces. A mixture of coarse rubber, metal cord and textile cord up to 50% by weight with mineral additives can be put into the road substrate. Further, the crumb – as a modifier of asphalt bitumen (chips less than 1.5 mm to 10% by volume), it is he who is the outer working layer of the roadway. The advantages are obvious: the physical and mechanical characteristics of the entire pavement are significantly improved (increased resistance to cracking and elasticity, as a result of which the frost resistance coefficient increases by 20-30%), which has a positive effect on the resource, the service life of the road pavement increases 2-3 times. Restoration of tires. Getting a regenerate. Up to 10% of the mass of crumb rubber obtained as a result of tire recycling can be used in the restoration and manufacture of new tires. For the manufacture of reclaim, rubber crumb of fraction up to 2 mm is mainly used. 10. For the manufacture of car parts. Bumpers, mud flaps, oil seals, floor mats, luggage compartment troughs, handles, etc. Small fraction rubber crumb is used as an additive in various automotive mastics. 11. Bridge coatings. When repairing bridges, joints are usually sealed with imported materials. The use of crumb rubber obtained as a result of tire processing in this direction will allow the use of 100% domestic materials, as a result of which the economy will be obtained on a national scale. Supports for main pipelines. When replacing existing supports located in permafrost areas, it is very beneficial to manufacture new concrete supports with the presence of crumb rubber. 13. Maintenance of oil and gas industries. For plugging oil wells during drilling, waterproofing green layers, for the manufacture of a sorbent for collecting oil and oil products from the surface of water and soil.

Send Me Quotation

The function is avialable for logged in users only

Reviews

There are no reviews yet.