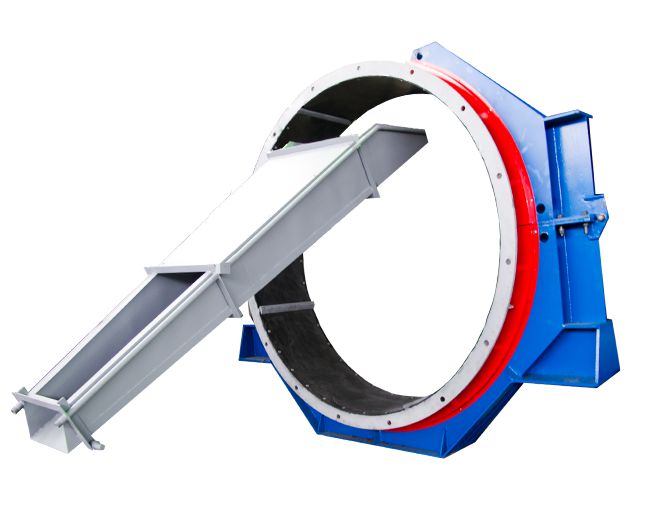

Installation magnetic scraping ERGA UMS

Price from: $ 1

Magnetic installation ERGA UMS continuously, in automatic mode, extracts fragments of grinding bodies from grinding products of ball, rod mills and semi-autogenous mills. • Protection of expensive equipment from breakdowns and premature wear. grinding ball, preventing wear and breakdown of conveying, classification, pumping equipment caused by the presence of metal parts and debris in the product. The magnetic scrap catcher 2-4 times reduces the wear rate of sump, pumps, hydrocyclones and pipelines, increasing their life cycle. Removal of scrap from the technological redistribution during enrichment of gold-bearing ore increases the yield of rough concentrate by 1.5% and the extraction of gold into rough gravity concentrate by 9.2% of the operation. reliable retention of small metal inclusions and prevention of their entrainment by the flow of material. • Individual solution for the standard size of the mill. magnetic installation is installed on the discharge flange of the ball mill drum. The drum is designed for butar mounting and has the same connecting dimensions, minimum size and is, in fact, a spacer. The magnetic system is installed on its own supports and requires preparation of the site for fastening. The discharge chute is installed cantilever on the supporting structure, provides continuous removal of the collected scrap outside the working area. The magnetic trunnion works without the participation of an operator and does not require special maintenance. • Automatic cleaning Cleaning of raw materials and materials from magnetic impurities occurs automatically and does not require personnel. removal of magnetic inclusions in automatic mode improves the quality of separation • Lack of energy consumption and increased energy efficiency The UMS magnetic scraper does not need electricity to generate a magnetic field. The guaranteed period of preservation of the properties of magnetic systems, subject to the rules of operation, is 10 years. High-quality extraction of worn out grinding bodies reduces the energy consumption of crushing equipment by up to 8% by eliminating the need to work with unnecessary load. • Additional lining of the magnetic system The working surface of the magnetic system is additionally protected from accelerated wear by means of a polyurethane lining. The removable lining significantly prolongs the service life of the working surface of the magnetic journal. * Development and production of magnetic UMS is carried out taking into account the connecting dimensions and the model of the customer's mill.

Send Me Quotation

The function is avialable for logged in users only

Specification

| Product value | 22,82 м3 |

| Product length | 2300 мм |

| Product width | 3200 мм |

| Product height | 3100 мм |

Reviews

There are no reviews yet.