Industrial equipment

| Image | Name | Summary | Categories |

|---|---|---|---|

| No130R Reducing Galvanized Pipe Fittings Tee | Malleable iron fittings Size Range: galvanized tee have threads on the inside of the fitting that screw onto the outside of the pipe, while non-threaded fittings are designed to be welded or soldered onto the pipe. depending on the type of pipe and fitting being used. | Industrial equipment | |

| Equal Tee Galvanized Malleable Iron Pipe Fittings No130 | Product Description Equal Tee galvanized malleable iron pipe fittings Cast Iron Fittings factory is located in CHINA (both manufacturing plants and foundry) and has been exporting fittings for the last 23 years all over the world. | Industrial equipment | |

| Galvanized Elbow 90 Degree Female Malleable Iron Pipe Fittings No90 | Product Description No90 Galvanized Elbow 90 Degree Female malleable iron pipe fittings are designed according to the EN 10242 standard and available in black and hot-dip galvanized versions. They are threaded according to EN 10226-1. The material ensures resistance against mechanical stress and long durability. | Industrial equipment | |

| Style Cast Iron Flange Adapter | SHORT DESCRIPTION STYLE Cast Iron FLANGE ADAPTER The gasket seating surfaces on the pipe and on the face of the mating flange must be free from gouges, indentations and deformities of any type for proper sealing. Refer to the installation instructions for complete information. • Vic-Flange Adapters must be assembled so there is no interference with mating components. | Industrial equipment | |

| Ductile Iron Grooved Equal Cross No180 | SHORT DESCRIPTION Generally, Ductile iron Grooved Equal Cross No180 is used to separate branches of a pipeline as a special pipe fitting. The grooved reducing cross is characterized by a reduced diameter, as opposed to other branches. The cross tee fittings is called a cross if both pipes are of the same diameter. A wide array of wholesale sanitary cross tee branches applications is performed by these fittings, including petrochemicals, oil, natural gas, power plants, food sanitation, building construction, and urban development. | Industrial equipment | |

| Threaded Grooved Mechanical Tee NPT Outlet | SHORT DESCRIPTION Threaded grooved mechanical tee NPT Outlet with threaded outlet (302) provides a direct branch connection at any location where a hole can be cut in the pipe. The gasket is a pressure-responsive design that provides the seal.

| Industrial equipment | |

| Mechanical-T Bolted Branch Outlet Style Victaulic Tee | SHORT DESCRIPTION MECHANICAL-T BOLTED BRANCH OUTLET STYLE Victaulic mechanical tee as part of grooved piping systems, use gaskets secured by housings to attach a new line of pipe to an existing one. The mechanical force from the bolts and nuts combined with the gasket and lubricant creates a tight seal around a hole drilled into a run of pipe. | Industrial equipment | |

| Grooved Equal Tee No130 | SHORT DESCRIPTION YINUO Grooved Equal Tee No130 ductile iron grooved fittings: Grooved Equal Tee No130 grooved piping system is reliable and is faster to install than welding, threading, or flanging, resulting in lowest installed cost. it can be adopted to suit standard pipe with cut grooves or standard and light wall pipe with rolled grooves. we are the exclusive agent of the mech brand ductile iron grooved fittings which has the UL/FM certificates. | Industrial equipment | |

| Grooved Rigid Coupling 3/4 Cast Iron Coupling YN01 | Product Description Grooved rigid coupling 3/4 cast iron Coupling YN01UL/FM APPROVED Rigid Coupling: Ductile Iron, 4 in x 4 in Fitting Pipe Size, Grooved, Class 150

China grooved pipe fittings are a proven faster, easier, and safer method of joining pipe and are an economical alternative to welding, threading, or using flanges. There are two basic grooved coupling styles: Flexible grooved couplings/fittings and Rigid grooved couplings/fittings. Flexible grooved couplings/fittings allow a limited amount of angular movement. Rigid grooved couplings/fittings do not allow movement and can be used wherever immobility in the pipe joint is needed, like a flanged or welded joint. | Industrial equipment | |

| Ductile Iron Grooved Elbow 90 Degree No90 | Product Description Ductile iron grooved elbow 90 Degree No90 are one type of Grooved fittings. We supply both Blue and RAL3000 for difference used.

China grooved pipe fittings have larger radius than elbows. Generally, the most basic difference is the radius of curvature. Elbows generally have a radius of curvature between one to twice the diameter of the pipe. Bends have a radius of curvature more than twice the diameter. | Industrial equipment | |

| Wholesale OEM Fire Protection Grooved Butterfly Valve Supplier | Products Details What is the Fire Protection Grooved Butterfly Valve?

Grooved butterfly valve (Gear actuator & tamper switch) is light weight valve with signal gearbox, and it is grooved connection. The valve is fully open or closed when the disc is rotated a quarter turn. The Grooved signal butterfly valve is a grooved clamp connection valve designed completely based on the principle of symmetry. It is symmetrical in the axial centerline, radially centerline, two-way full pressure seal, with a signal device, which can give the valve action. It is mainly used in various pipelines of water supply and drainage, building fire protection and other systems, especially in fire protection pipelines, to cut off and adjust the flow of the medium. | Industrial equipment | |

| Best OEM Flanged End Resilient Wedge OS &Y Gate valve Z41-300 For Sale | PRODUCTS DETAILS: What is the Resilient Seated OS&Y Type Flange Gate Valve? A gate valve is an industrial valve that controls the flow of fluid by raising or lowering a gate (flat or wedge-shaped valve) within the valve. When the gate is raised, it allows fluid to pass through, and when lowered, it blocks the flow. OS&Y stands for “Outside Screw and Yoke,” which is a specific design feature of some gate valves. In an OS&Y gate valve, the valve’s operating screw is located on the outside of the valve body and attached to the yoke. This design allows easy identification of the valve’s position (open or closed) and protects the valve stem threads from fluids, preventing corrosion and damage. The flange end resilient wedge OS&Y gate valve is a gate valve with specific characteristics: Flange Ends: The fire protection valves has flanges on both ends that allow it to be easily installed and bolted to the piping system. Resilient Wedge: The term “resilient wedge” refers to the type of gate used in valves. The elastic wedge gate is designed to deform slightly, ensuring a tight seal on the valve seat even in the presence of foreign particles or slight misalignment. OS&Y (External Screw and Yoke): As mentioned previously, this design feature allows the stem screw to be accessed from the outside and provides clear visibility of the valve position. This type of gate valve is commonly used in a variety of industries, including oil and gas, water treatment, and other applications that require reliable, visible fluid flow control.

| Industrial equipment | |

| China OEM Flanged End Resilient Wedge NRS Gate Valve Factory | PRODUCTS DETAILS: what is the Flanged End Resilient Wedge NRS Gate Valve Z45 200PSI type ? The Flange End Resilient Wedge NRS (Concealed Stem) Gate Valve Z45 rated to 200 PSI is a specific type of fire protection valve designed for use in a variety of applications including water distribution and industrial processes. Let’s break down the main features: Flange End: The valve has a flange end that allows for a secure bolted connection to the pipes in the piping system. Flanges are a common method of connecting valves in water and industrial systems. Resilient Wedges: Resilient wedge designs utilize flexible wedges made of materials such as rubber or EPDM. This design helps the valve maintain a tight seal even if debris or sediment is present in the pipe. NRS (non-rising stem): Indicates that the valve stem does not rise when the valve is opened. In a concealed stem gate valve, the valve stem remains in a fixed position while the gate plate moves up and down to control the flow. This design is often used in applications where space is limited. 200 PSI Rating: This valve is designed to handle a maximum pressure of 200 pounds per square inch (PSI). This pressure rating represents the maximum pressure the valve can withstand without failure. Flange Ended Resilient Wedge NRS Gate Valve Type Z45 200PSI is commonly used in water supply systems, wastewater treatment plants and a variety of industrial processes where reliable flow control and sealing are critical. It’s important to note that valve specifics, such as size, materials, and compliance with industry standards, may vary depending on the manufacturer. If you require detailed information on a specific Z45 valve, it is recommended to refer to the product documentation provided by the manufacturer or contact them directly for accurate specifications. | Industrial equipment | |

| China High Quality Grooved Cross Manufacturer | Products Details Ductile iron Grooved pipe fittings Equal Tee. The material is ductile iron. The connect method is Grooved connection. The Grooved Tee also called DI Grooved tee. Grooved Tee have Grooved tee short, Grooved tee long radius 90 degree. Grooved Reducing Tee, Grooved tee with Thread outlet, also called Thread Grooved Tee, normaly the branch outlet is thread end ,the main outlet is Grooved end. According to the surface coating ,dip painting Grooved Tee red color ,epoxy red color Grooved Tee ,epoxy blue color Tee ,galvanized Grooved tee. | Industrial equipment | |

| High Quality OEM Grooved 45° Elbow Manufacturer | Products Details Grooved 45° Elbows are a special type of pipe fitting used in grooved piping systems. Grooved duct systems are known for their ease of installation and versatility. Groove design allows for quick, direct connections without soldering. Here is some information about fluted 45° elbows: | Industrial equipment | |

| Wholesale Best Angle Pad Grooved Pipe Coupling Supplier | Products Details Grooved pipe couplings are mechanical connectors used to join pipes in a variety of applications, providing a flexible and efficient method for assembling and disassembling piping systems. These couplings usually consist of two housings with washers between them and secured by bolts or nuts. It is used for grooved pipe connections. At the joint, the adjacent pipe ends are not allowed to have relative angular displacement and corresponding axial rotation. The two butt joints of this product are inclined grooved pipe joints. Standards related to grooved pipe joints generally address design, dimensions, materials, and testing requirements. Some common standards for grooved pipe couplings include: ASTM A536: This standard covers ductile iron castings for a variety of applications, including grooved pipe joints. ASTM A795: This standard specifies black and hot-dip galvanized (galvanized) welded and seamless steel pipe for fire protection applications and may involve the use of grooved joints. UL 213: Underwriters Laboratories (UL) Standard for Grooved Mechanical Joints and Fittings for Fire Service. FM (Factory Mutual) Certification: FM Global has specific standards for grooved pipe couplings and related components used in fire protection systems. | Industrial equipment | |

| High Quality Iron fittings Galvanized Elbow Manufacturer | Code:90 Size: 1/8”-6” Material: BS EN 1562,EN-GJMB-350-10,KTH350-10 Dimension: BS EN 10242 Thread: ISO 7-1,BS 21,BSPT Pressure Rating: PN16/PN25 Surface Treatment: Hot-dip Galvanized,Electro Galvanized,Black Application: Fire Protection, Waterworks, HVAC, Plumbing, GAS, Irrigation, or other piping systems | Industrial equipment | |

| China Malleable Iron 1221 Side Outlet Elbow BSPT Thread Supplier | Code:1221 Size: 1/2”-1” Material: BS EN 1562,EN-GJMB-350-10,KTH350-10 Dimension: BS EN 10242 Thread: ISO 7-1,BS 21,BSPT Pressure Rating: PN16/PN25 Surface Treatment: Hot-dip Galvanized,Electro Galvanized,Black Certificate: UL Listed / FM Approved / NSF 61 Application: Fire Protection, Waterworks, HVAC, Plumbing, GAS, Irrigation, or other piping systems | Industrial equipment | |

| Best Malleable Iron 120 Elbow 45° BSPT Thread For Sale | Code:120 Size: 1/4”-6” Material: BS EN 1562,EN-GJMB-350-10,KTH350-10 Dimension: BS EN 10242 Thread: ISO 7-1,BS 21,BSPT Pressure Rating: PN16/PN25 Surface Treatment: Hot-dip Galvanized,Electro Galvanized,Black Certificate: UL Listed / FM Approved / NSF 61 Application: Fire Protection, Waterworks, HVAC, Plumbing, GAS, Irrigation, or other piping systems | Industrial equipment | |

| China Wholesale Malleable Iron 130 Equal Tee BSPT Thread Factory | Products Details Malleable Iron pipe fittings 130 Equal Tee . Code is 130. Main outlet and branch outlet is same. We have three type tee, heavy type tee with UL/FM certificate ,medium type tee and light beaded tee. According to the Surface treatment, hot dip Galvanized tee ,electro plate Galvanized tee or cold Galvanized tee ,and black tee. According to the Threaded Standard, there are have NPT Thread tee ,BSP thread tee ,and ISO228 thread tee. If the main outlet and branch outlet is difference ,we called it is Tee reducing. | Industrial equipment | |

| Light tower Mini | Emergency lighting installation "Light pole" (EMERCOM pole, light tower) is intended for emergency deployment on the ground in case of natural and man-made disasters, in case of unauthorized switching off of lighting, to illuminate large areas at public events, as well as during night work in industry and construction in hard-to-reach places without the use of expensive equipment and qualified personnel. | Industrial equipment | |

| Light Tower | Emergency lighting installation "Light pole" (EMERCOM pole, light tower) is intended for emergency deployment on the ground in case of natural and man-made disasters, in case of unauthorized switching off of lighting, to illuminate large areas at public events, as well as during night work in industry and construction in hard-to-reach places without the use of expensive equipment and qualified personnel. Those. specifications Technical characteristics: 1) Power supply – Single-phase AC power grid with a voltage of 220 V, 50 Hz, two-phase AC power grid with a voltage of 380 V, 50 Hz or from an autonomous power plant 2) Light source – High pressure gas discharge lamp DNaT, DNaZ, DRI with a power of 600 W. 3) Luminous flux 48,000 – 120,000 lm. It is possible to install two or more lamps. 4) Compressor with a capacity of 150 to 1200 W., with a capacity of 2.5 – 3.5 cubic meters / min, with an overpressure of 10,000 – 14,000 Pa. 5) Dimensions – 600x450x500 mm. (dimensions may vary depending on the selected type of installation). 6) Height of the installation in working condition – 7 m. 7) Total weight – 65 kg. Weight may vary depending on the configuration. 8) Inflation time of the fabric cylinder – 1 minute, the time of full lighting of the lamp – 5 min. version – U11) Category of placement according to GOST 1515012) Degree of protection – IP 65/4413) Class of protection against electric shock – II14) Light distribution class P according to GOST 17677. | Industrial equipment | |

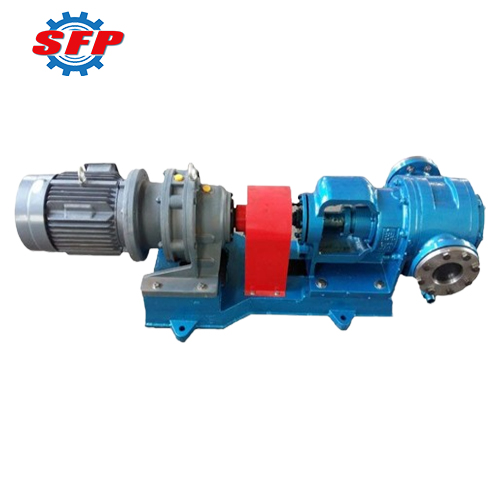

| High Performance ZYB Series Gear Oil Pump for Heavy Oil and Fuel Oil | The ZYB series waste oil pump is used for pumping impurities including heavy oil, diesel oil, coal tar and grain, oil, chemical, building materials and daily chemical products with a temperature not higher than 200℃ and a viscosity of not more than 150 mm 2 /S containing non-metallic impurities. This machine adopts self-sealing lubrication design, the gap automatically adjusts the structure, and the parts are made of high wear-resistant materials. | Industrial equipment | |

| Wholesale Electric NYP Series High Viscosity Liquid Transfer Gear Oil Pump | NYP internal gear oil pump is a new type of positive displacement pump, which is designed according to the needs of different fields such as petroleum, chemical, paint, medicine, food and so on. Through special structural form and selection of different pump materials, it can be widely used in a variety of media with different properties and viscosities. | Industrial equipment | |

| Honing machine | Horizontal Honing Machines:MRL-1800/MRL1805,LH100/CH100,vertical honing machine:MVR-200,DWVH-200-760 | Industrial equipment | |

| Plumbing, faucet, tap, bathroom faucet, sink faucet, basin mixer, bathtub mixer, shower mixer | Model MS1008, SPRING commercial stainless steel sink faucet,stainless steel sink faucet,stainless steel kitchen sink faucet,stainless steel sink black faucet | Industrial equipment | |

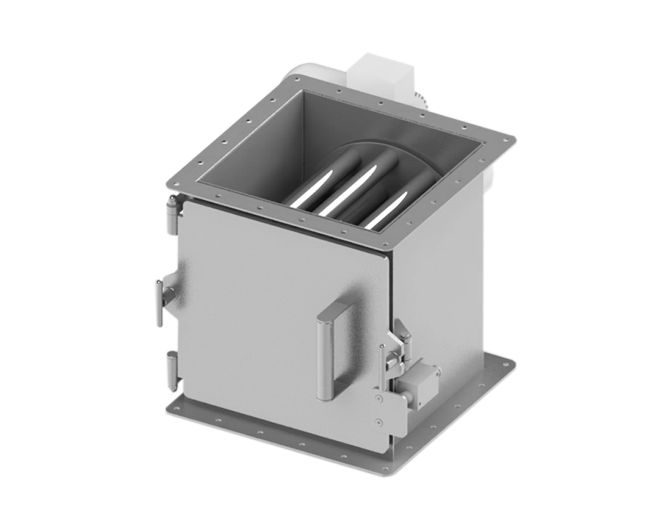

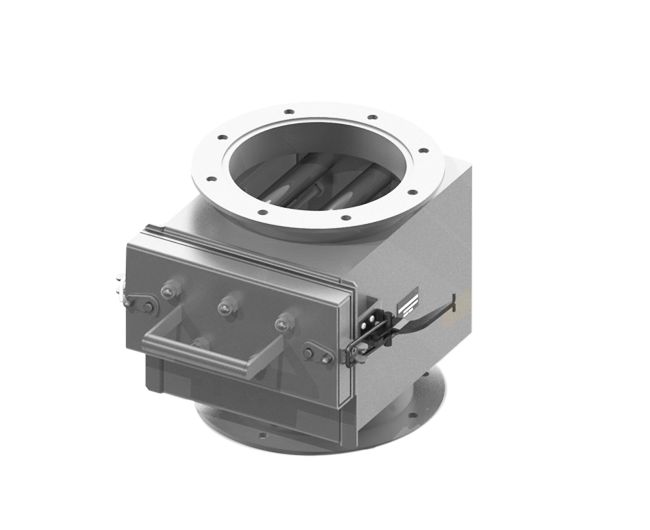

| Swinging screen ERGA GK | The oscillating screen ERGA GK provides simultaneous screening of up to 5 fractions of material with a classification efficiency of up to 99%. TECHNOLOGICAL DESIGN ERGA GK screen is a sealed, dust-proof housing with replaceable sieves (up to 4 pcs) installed inside. During sieving, the entire sieve area is involved, which ensures high productivity of the equipment. CLASSIFICATION EFFICIENCY UP TO 99% Individual sieving mode is selected depending on the material and requirements for the final product. Optimal adjustment of the sieve angle, stroke amplitude and pulse frequency allow achieving up to 99% efficiency of the classification of the source material. OPERATION UP TO 24 HOURS PER DAY WITH MINIMUM MAINTENANCE Unpretentious, rocking screen ERGA GK works without complicated transmission mechanisms, lubrication and close attention from the personnel. The sieves are cleaned automatically, which eliminates their clogging and guarantees high-quality fractionation of raw materials with high productivity without downtime for maintenance. If it is necessary to replace the sieve, it is enough to unblock the eccentric clamps and remove the sieve. | Industrial equipment | |

| Precision laser marking marker MiniMarker 2-C25 | A compact laser machine performs special processing on the surface of all types of alloys, including precious metals (gold, platinum, titanium, etc.) without harm to the integrity of the surface of this material. MiniMarker laser machines are highly reliable (they have been operating in production for more than 12 years), have low power consumption, no need for consumables, provides high quality images, has the ability to color laser engraving of metals, has an extended warranty of 3 years. The customer's personnel undergo free short-term training.The MiniMarker 2-C25 laser machine is recommended for special marking, including marking of medical devices, aircraft engine parts (turbine blades, pipelines, etc.), end surfaces of precision bearings. Those. specifications laser emitter: Laser type: ytterbium cw fiber Laser resource: more than 100,000 hours Average laser output power: 25 W Laser wavelength: 1.064 μm Cooling: autonomous air software package: Type of output images: outline and raster, text and graphic, barcode | Industrial equipment | |

| PET BOTTLES WASHING LINE | Industrial equipment | ||

| Screw-cutting lathe 165 | Industrial equipment | ||

| Rotator (manipulator) welding MAK-70N, carrying capacity up to 70 kg. | Welding rotator MAK-70N with a maximum carrying capacity of 70 kg, designed to hold and position the product during welding. Rotation is carried out by a domestic-made DC geared motor, which provides smooth regulation and stability of the rotation speed. The faceplate is tilted manually using a clamping lever. A sliding contact (copper-bronze) with a load of 500 A is used to connect the return welding cable. All electrical parts are located in the rotator body. Those. specifications Distinctive features of the MAK-70N rotator: – strong base, which ensures stability of rotation of the product without vibrations at various weights and configurations; – motorized rotation of the faceplate in a wide range of speeds; in which you can install the welded product; – operating mode: 2-stroke, 4-stroke – change the direction of rotation – the ability to rotate the faceplate at the marching (maximum) speed for quick installation of the product; – LED indication of the rotational speed of the faceplate (in rpm); – start and stop rotation using a foot pedal. Technical characteristics Maximum lifting capacity * – 70 kg Maximum torque – 15 kg * m Faceplate diameter – 420 mm Rotation speed – 0.5-8.45 rpm Tilt angle – 0 – 90 degrees Supply voltage – 1×220 (50 Hz) H Weight – 73 kg Overall dimensions (HxLxW) – 835x420x670 mm | Industrial equipment | |

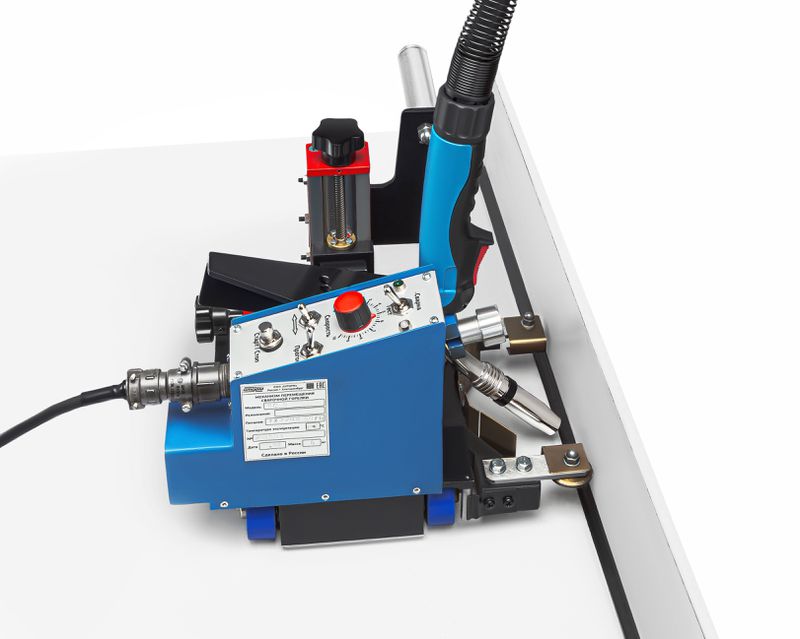

| Torch travel mechanism for vertical and horizontal fillet welds in confined spaces KC-5 | The KS-5 welding torch travel mechanism is designed for MIG / MAG fillet welds without transverse oscillations of the torch. Small dimensions of the mechanism make it possible to use it in confined spaces and hard-to-reach places. Distinctive features: – strong metal base; – aluminum wheels covered with special heat-resistant rubber, which ensures the operation of the mechanism on surfaces heated to 250 ° C and a long service life; – powerful magnetic system , providing free movement of the mechanism on inclined and vertical surfaces; – all-wheel drive system of movement of the mechanism allows you to maintain a constant speed of movement even on an uneven surface; – the ability to work with almost any welding machine; – manual supports, providing easy positioning of the torch in two directions when setting the process and correction of its position during welding; – ensuring the constancy of the position of the mechanism relative to the joint during welding due to the copying system, which consists of two thrust rollers mounted on an adjustable axis; – a convenient handle for tearing of the mechanism from the product and transportation; – low weight and dimensions of the mechanism; – favorable price offer. An excellent choice for welding horizontal fillet welds and welding in a confined space, a simplified device, an advantageous price offer. Those. specifications Welding position – Horizontal fillet weld Weight – 8 kg Dimensions: HxWxL – 300x210x260 mm Power supply AC 1 ~ 100-240 V (frequency 50-60 Hz) Ground clearance – 6.5 mm (fixed) Number of driving wheels 4 – on fixed axle Number of thrust rollers 2 – on an adjustable axis (adjustment angle ± 1 ° 40 ") Torch travel – horizontal – 50 mm – vertical – 50mm Burner tilt angle along the axis – 45 ± 10 degrees along the Y axis – 90 ± 10 degrees Carriage speed 5 to 60 cm / min Clamping device – magnetic Clamping force – 25 kg Welding torch * – with straight or curved neck, 350 A (500 A), 3 m (4.5 m) | Industrial equipment | |

| Rotator (manipulator) welding MINI-15, carrying capacity up to 15 kg. | Description – digital indication of the rotational speed of the plate washer; – simple and intuitive control; – modular design provides convenient location at the workplace; – the plate with 6 slots, which allows you to install any types of cartridges and various devices on it; – manual tilt with fixing the position of the drive unit with clamping levers. Those. specifications Power supply: AC -230 V, frequency 50/60 Hz Rotation speed of the faceplate: 1-9 rpm Reverse of rotation: yes Loading capacity: 15 kg Height of the rotator – 360 mm Height to the axis of rotation in the horizontal position – 205 mm Diameter of the faceplate – 180 mm Number of grooves in the plan-washer – 6 pieces Width of the base – 145 mm Base length – 320 mm Weight: rotator – 15.6 kg control unit – 3.4 kg pedal – 1.2 kg Scope of delivery: 1. welding rotator Mini 15 – 1 pc. 2. control unit with a 3 m network cable – 1 pc. 3. foot pedal – 1 pc. 4. set of operational documentation – 1 pc. Additionally, we recommend purchasing: cartridge – 1 pc. (not included in delivery) | Industrial equipment | |

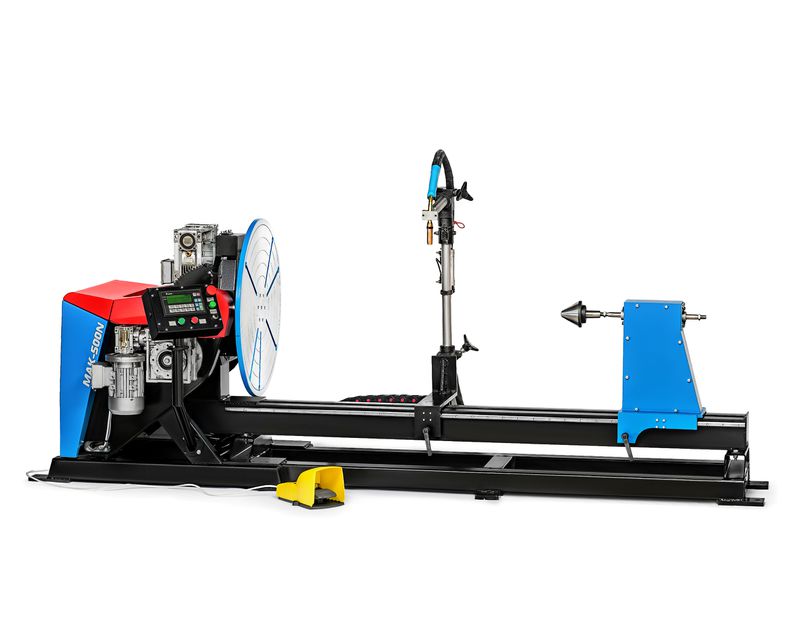

| Rotator (manipulator) welding МАК-500N, carrying capacity up to 500 kg. | Rotation and tilt is carried out by a Russian-made geared motor, which provides smooth adjustment and stability of the rotation speed. To connect the return welding cable, a sliding contact (copper-bronze) with a load of 500 A. control panel. Distinctive features of the MAK-500N welding rotator (manipulator): – strong welded base, which provides stability of rotation of the product without vibrations at various weights and configurations; motorized rotation and tilt of the faceplate in a wide range of speeds; – faceplate with six slots suitable for mounting various types cartridges or special devices in which the welded product can be installed; – manual and automatic operation; – the ability to customize the full cycle of work, including setting the start delay time, overlap value, control of the welding machine; – multifunctional panel with a full-text display provides easy control and setting the operating mode of the rotator; – the possibility of installing one or several pneumatic arms to hold the burner; – the rotator can be equipped with a tailstock moving along an additional base for fixing products of great length up to 2000 mm. Those. specifications Technical characteristicsMaximum lifting capacity – 500 kgMaximum bending moment – 120 kg * mMaximum torque – 90 kg * m Faceplate diameter – 700 mm Rotation speed 0.1-1.0 rpm Tilt angle 0 – 105 degrees Power supply – 3х380 (50Hz) VW – 398 kg Overall dimensions – 1090х840х825 mm Pneumatic console – option Tailstock – option | Industrial equipment | |

| Rotator (manipulator) welding МАК-200N, carrying capacity up to 200 kg. | Rotation is carried out by a Russian-made gear motor, which provides smooth adjustment and stable rotation speed. The tilt is carried out manually, due to the rotation of the handwheel (on request, it can be retrofitted with a geared motor) To connect the return welding cable, a sliding contact (copper-bronze) with a load of up to 500 A is used. built-in control panel Distinctive features of the rotator (manipulator) of welding MAK-200N: – strong welded base, which provides stability of rotation of the product without vibrations at different weight and configuration; – motorized rotation and tilt (on request) of the faceplate in a wide range of speeds; – a faceplate with six slots is suitable for fastening various types of cartridges or special devices in which the workpiece to be welded can be installed; – manual and automatic operating modes; – the ability to customize the full cycle of work, including setting the start delay time, overlap value, control of the welding machine; – multifunctional pan a spruce tree with a full-text display provides easy control and adjustment of the rotator's operating mode; – the ability to install one or several pneumatic arms to hold the torch; – the rotator can be equipped with a tailstock moving along an additional base for fixing long products up to 2000 mm. Those. specifications Maximum lifting capacity – 200 kg Maximum bending moment – 80 kg * m Maximum torque – 38 kg * m Faceplate diameter – 650 mm Rotation speed 0,4-4,0 rpm Tilt angle 0 – 105 degrees Power supply -220 V (50Hz) Weight – 295 kg Overall dimensions mm -1050х850х730 Pneumatic console – option Tailstock – option ** lifting capacity is indicated in the horizontal position of the plan-washer | Industrial equipment | |

| Rotator (manipulator) welding МАК-200N BA with pneumatic console, carrying capacity up to 200 kg. | Welding rotator MAK-200N BA with a pneumatic console for positioning the welding torch, carrying capacity up to 200 kg, is designed to hold and position the product during welding. Rotation is carried out by a Russian-made gear motor, which provides smooth adjustment and stable rotation speed. The tilt is carried out manually, due to the rotation of the handwheel (on request, it can be retrofitted with a geared motor) To connect the return welding cable, a sliding contact (copper-bronze) with a load of up to 500 A is used. built-in control panel. Distinctive features of the rotator (manipulator) of welding MAK-200N BA: – strong welded base, which provides stability of rotation of the product without vibrations with different weight and configuration; – motorized rotation and tilt (on request) of the faceplate in a wide range of speeds; – a faceplate with six slots is suitable for fastening various types of cartridges or special devices in which the workpiece to be welded can be installed; – manual and automatic operating modes; – the ability to customize the full cycle of work, including setting the start delay time, overlap value, control of the welding machine ; – multifunctional a panel with a full-text display provides – easy control and setting of the rotator's operating mode; – equipped with a pneumatic console to hold the torch; – the rotator can be equipped with a tailstock moving along an additional base for fastening products of great length up to 2000 mm. Those. specifications Maximum lifting capacity ** – 200 kg Maximum bending moment – 80 kg * m Maximum torque – 38 kg * m Faceplate diameter – 650 mm Rotation speed – 0.4-4.0 rpm Tilt angle 0 – 105 degrees Power supply – 220 V (50Hz) Weight – 295 kg Overall dimensions mm – 1050х850х730 Pneumatic console – yes Tailstock – option ** lifting capacity is indicated in the horizontal position of the plan-washer | Industrial equipment | |

| Rotator (manipulator) welding МАК-500N BACB with tailstock and pneumatic console, lifting capacity up to 500 kg. | Welding rotator MAK-500N BACB with a tailstock and a pneumatic console with a lifting capacity of up to 500 kg is designed to hold and position a product up to 2000 mm long during welding. Rotation and tilt is carried out by a Russian-made gear motor, which provides smooth adjustment and stability of the rotation speed. The cable uses a sliding contact (copper-bronze) with a load of 500 A. Setting and regulation of rotation, tilt, and welding parameters is performed on the built-in control panel. Those. specifications Distinctive features of the rotator (manipulator) of welding MAK-500N BACB: – strong welded base, which ensures stability of rotation of the product without vibrations at different weight and configuration; – motorized rotation and tilt of the faceplate in a wide range of speeds; – faceplate with six slots is suitable for fastening of various types of cartridges or special devices in which the welded product can be installed; – manual and automatic operating modes; – the ability to customize the full cycle of work, including setting the start delay time, overlap value, control of the welding machine; – multifunctional panel with full-text display provides easy control and adjustment of the rotator operating mode; – the rotator is equipped with a tailstock with a pneumatic console moving along an additional base for securing products of great length up to 2000 mm. | Industrial equipment | |

| Rotator (manipulator) welding МАК-200N BACB with tailstock and pneumatic console, lifting capacity up to 200 kg. | Welding rotator MAK-200N BACB with a tailstock and a pneumatic console, carrying capacity up to 200 kg., Is designed to hold and position the product during welding. Rotation is carried out by a Russian-made gear motor, which provides smooth adjustment and stable rotation speed. The tilt is carried out manually, due to the rotation of the handwheel (on request, it can be retrofitted with a geared motor) To connect the return welding cable, a sliding contact (copper-bronze) with a load of up to 500 A is used. built-in control panel. Distinctive features of the rotator (manipulator) of welding MAK-200N BAСВ: – strong welded base, which provides stability of rotation of the product without vibrations with different weight and configuration; – motorized rotation and tilt (on request) of the faceplate in a wide range of speeds; – a faceplate with six slots is suitable for fastening various types of cartridges or special devices into which the work piece to be welded can be installed; – manual and automatic operating modes; – the ability to customize the full cycle of work, including setting the start delay time, overlap value, control of the welding machine ; – multifunctional a panel with a full-text display provides easy control and adjustment of the rotator operating mode; – equipped with a pneumatic console to hold the torch; – the rotator can be equipped with a tailstock moving along an additional base for securing products of great length up to 2000 mm. Those. specifications Maximum lifting capacity ** – 200 kg Maximum bending moment – 80 kg * m Maximum torque – 38 kg * m Faceplate diameter – 650 mm Rotation speed -0.4-4.0 rpm Tilt angle 0 – 105 degrees Power supply 220 V (50 Hz) Pneumatic console – there is a tailstock – there is | Industrial equipment | |

| Roar GST-61 | Industrial equipment | ||

| Booster pumps | The pump design significantly reduces static and dynamic loads on radial bearings. The level of noise and vibration of vertical pumps is significantly lower, booster pumps have a long service life. They differ in such advantages as: – energy saving – sealed design – no leakage, no environmental pollution – the flow path is unified with the central nervous system pump of the PPD system – increased reliability – not required alignment, capital foundation – it is possible to install an upstream multiphase wheel (auger) Tech. specifications Consumption, m3 / hour: from 45 to 300. Head, m: from 100 to 200. Seal: double face. | Industrial equipment | |

| Full polypropylene mold filters | Our company produces Nutsche filters from polypropylene. Also we can offer other thermoplastic materials (PVC, PEHD, PVDF) for specific solutions. Nutsche filters are used for filtration and thickening of solutions. Nutsche is the simplest batch-type filter working under vacuum or overpressure. Direction of gravity and movements of filtrate are the same in it. Nutsche filters can be of 2 types: open and closed filters. Nutsche filter of open type works under discharging. Such kind of filter is a device of rectangular or round shape equipped with the filter baffle plate above the bottom. Filter can be made from cloth, thermoplastic perforated sheets or other materials which is laid on grid. After the filter is filled with suspension and vacuum is blowing the filterable substance goes through the baffle plate. Sediments remain on the baffle plate. After the process is completed the sediments are removed manually. The device can be equipped with a mobile bottom to simplify the processes of unloading. Advantage of open Nutsche filters from PP is its simple and safe design which enables to wash sediments carefully. Nutsche filters are made from polypropylene. Therefore they are resistant to aggressive mediums and operate by the temperature from -5 till + 95 С°. Nutsche filter of closed type works under overpressure. It consists from the case with a jacket, removable cover and mobile bottom. The filter baffle plate is placed on support grid. This plate can be made from guard mesh, layers of fibers or perforated sheets. Ring plate is placed above the filter baffle plate. It holds the sediments by uploading. The bottom is movable: it can turn and descend at an angle suitable for manual removing of sediments from the filter plate. Nutsche filter is provided with nozzles to supply suspension, compressed air or to remove filtrate. The filter is equipped with safety valve to prevent the pressure rise above the limit. By the filtration under overpressure the saturated steam is supplied into the jacket. It ensures the viscosity reduction of filtrate and increases the efficiency. | Industrial equipment | |

| Polypropylene chemical reactor | A chemical reactor is a unit for carrying out stable and stable chemical processes with strict adherence to the necessary parameters of the process (temperature, mixing speed and dosing of components). The main purpose of chemical reactors is to produce the final product from the initial components. The main material for manufacturing the reactor is polypropylene, since the medium is usually very aggressive, it is also possible to manufacture it from other polymers (polyethylene, PVC, PVDF). | Industrial equipment | |

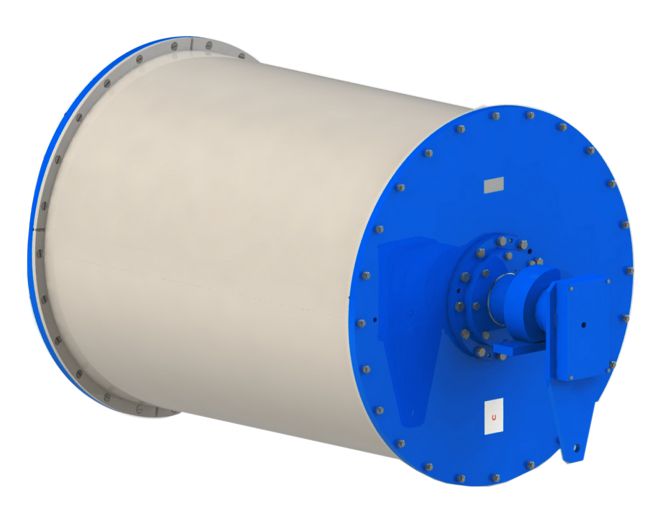

| Polypropylene fans | The main specialization of the company "UralAktiv", Yekaterinburg is the production and supply of industrial polymer radial fans in acid-proof design, all standard sizes of low pressure hoses, medium high pressure hoses and high high pressure hoses, with a capacity from 500 m3 / h to 150 000 m3 / h and pressure up to 8 000 Pa for various chemical environments containing acids and alkalis and with a service life of up to 50 years in corrosive gases. | Industrial equipment | |

| Nutsch filter | Our company produces Nutsch filters from polypropylene, but for specific solutions we can offer other thermoplastics (PVC, HDPE, PVDF). Nutsch filters are used to filter or thicken a solution. Nutsch is the simplest batch filter operating under vacuum or overpressure … The directions of gravity and the movement of the filtrate in it coincide. There are two types of suction filters: open and closed. | Industrial equipment | |

| Galvanic polypropylene baths | The main specialization of UralAktiv LLC is the production of polypropylene ventilation for electroplating industries. On the basis of our company, we have the ability to develop and manufacture any type of electroplating baths made of polypropylene. The material for making electroplating baths depends on the set, concentration and temperature of the acids used in the process. The most versatile are polypropylene baths due to their availability and good chemical resistance. Available materials for plastic electroplating baths: PP, Polypropylene (made in Russia); PP, Polyproipilene (imported); PVC, polyvinyl chloride; PVDF, polyvinyldene fluoride. Polypropylene electroplating baths already contain stiffeners, and for large galvanic baths, steel is used outer frame. The size of the electroplating baths directly depends on the size of the workpiece in this process, which is why most often the electroplating baths are designed and manufactured according to the specific requirements of the client. Polypropylene electroplating baths are suitable for most electroplating processes: polishing, chromating, zinc plating, nickel plating, cadmium plating, copper plating, varnishing, brass plating, parts washing and drying. In addition to baths, our company can manufacture electroplating tables and drums. Drums allow galvanic processing of small metal products and all hardware products. For example: studs, bolts, nails, metal fittings, etc. A galvanic drum, as a component unit, can be included in drum suspensions (carriages) and drum baths. Reels of all types and sizes are produced, depending on the dimensions of the baths and transport equipment of the customer's galvanic lines. Plating baths made of plastic are much more reliable than metal or stainless steel baths and much cheaper than electroplating baths made of special steels. At the same time, they are lighter and have a better appearance. The service life of such galvanic baths is from 10 to 50 years. | Industrial equipment | |

| Containers made of polyethylene and polypropylene | On the basis of our company, we design and manufacture containers from polypropylene and polyethylene based on sheet materials. The most optimal and economically feasible design of a polypropylene container is a vertical cylindrical shape. Horizontal containers made of polypropylene, as a rule, are made by our company of rectangular shape with additional stiffening ribs. It is better to make horizontal polyethylene tanks (polyethylene tanks) from finished pipes of the required diameter, since they have the maximum ring stiffness. Polyethylene (polypropylene) containers can be used for storing drinking water or storing aggressive liquids (solutions of acids and alkalis). The material of the acid container is selected individually, depending on the temperature, composition and concentration of acids. So, for example, polyethylene is the best material for a sulfuric acid container. It should be noted that the service life of a polypropylene container is maximum if it is located inside a heated room. For outdoor use, polyethylene is more suitable. There are the following types of plastic containers: Vertical cylindrical containers: containers with a flat bottom containers with a conical bottom containers with a conical lid containers with a conical bottom and a conical lid Horizontal conical containers Rectangular containers Containers for transporting corrosive liquids from thermoplastics Tech. specifications Vertical cylindrical tanks Flat-bottomed tanks Vertical-type plastic cylindrical tanks with a flat bottom are intended for stationary storage of both drinking water and aggressive chemicals. The material from which the containers are made is suitable for contact with food and chemical media. The main material for containers, tanks, reservoirs is polypropylene in gray RAL7032 and black polyethylene. Other types of materials and colors are available on special order. Available types of plastics: PP / PP – polypropylene; PPs – Flame Retardant Polypropylene; PP-EL-s – electrically conductive, flame retardant polypropylene; PE / PE – polyethylene; PVC – polyvinyl chloride; PVDF stands for polyvinylidene fluoride. At the request of the customer, we manufacture in other sizes, and, if necessary, we will help to complete additionally: level sensors, a pump, a stirrer, heaters, etc. Containers with a conical bottom The company UralAktiv LLC manufactures polymer containers with a conical bottom. All of them can be made of durable chemically resistant plastic, for example, polypropylene sheet, polyethylene sheet. Their bottoms are tapered and the drain hole is located at the bottom of the tank. Thanks to this design, you can use absolutely all the contents of the container, and the sediment does not accumulate on the bottom. Containers with a conical lid We make cylindrical plastic containers with a flat bottom and a conical lid from polypropylene, from polyethylene. This version of the lid makes it possible to manufacture containers with a large volume. Polymer containers with a conical lid are conveniently used in various technological processes, for example, in the metallurgical, chemical or food industries and not only: it can be energy, mechanical engineering and household use, for example, for storing water. Tanks to order can be completed with additional equipment, such as: level gauges, taps, nozzles, etc. Tanks with a conical bottom and a conical lid Our company also calculates, designs and manufactures more complex containers, for example, with a conical bottom, conical lid, supports. For additional strength, stiffening belts are provided. Equipment can be installed on all containers, tanks, reservoirs made of polypropylene, polyethylene: agitators, pumps, level sensors, shut-off valves, electric heaters, instrumentation and much more. for a more convenient location. Horizontal tanks made of chemically resistant plastic (PP, PE) are designed for storing drinking water, food, as well as aggressive acids and alkalis. Temperature range of storage of liquids in plastic containers from -40 to + 90 degrees Celsius. At the request of the customer, the complete set can be different: fittings, bends, level gauges and other equipment. | Industrial equipment | |

| Vertical scrubbers | An absorber (absorption column) is a mass transfer apparatus used to separate gas mixtures by selective absorption of individual components by an absorbent. Typically, absorption columns are used for the production of ammonia, chlorine and sulfuric acid. Absorption columns are: – Packed absorbers. – Disc (bubble) absorbers. – Tubular absorbers. Absorption plants manufactured by us are made of polymeric materials (polypropylene, polyethylene, PVC, PVDF), as well as all fittings, an irrigation system from a pump to nozzles and instrumentation. Maksimova vertical gas scrubbers The model of a vertical wet scrubber type VM is designed to remove most acids, alkalis and their mixtures, including impurity gases. Principle of operation: Gas scrubber VM has a sufficiently large packed bed, which makes it possible to use this scrubber as an absorber. The air flow passes through the bed of the packing from the bottom to the top, which is continuously sprayed with water (solution) using nozzles. Due to the large volume of the nozzle, the contact area of the liquid contact with the gas-air mixture increases, thereby increasing the cleaning efficiency. Further, the air flow enters the droplet separators, where the scrubbing liquid is separated from the gas-air mixture. Due to the bends of the droplet separator profile, moisture droplets settle on the surface and roll down, falling into the packed bed. The sprinkling liquid, passing through the nozzle layer through the water seal, enters the buffer tank. The water seal makes it possible for the scrubber to operate under vacuum. Further, the liquid is fed back to the flushing by means of the pump. In addition, the scrubber can be equipped with a coalescer. The coalescer is positioned between the elements of the droplet separator in such a way that even the smallest droplets are enlarged and then separated on the droplet separators. Those. specifications Vertical scrubbers are divided into three types by flow velocity: VM-05 – scrubber with a flow velocity of 0.5 m / s, resistance up to 550 Pa; VM-1 – scrubber with a flow velocity of 1.0 m / s, resistance up to 600 Pa ; VM-2 – scrubber with a flow rate of 2.0 m / s, resistance up to 650 Pa. | Industrial equipment | |

| Industrial laboratory furniture | Our company is engaged in the production of laboratory furniture for research facilities and industrial enterprises: tables; countertops; sinks; fume hoods; cabinets for storage and overflow of aggressive media. All products are certified by ROSTEST. Order furniture of all sizes and configurations. Polypropylene furniture can withstand heavy loads and is equipped with equipment for connecting to a water supply system, sockets, wheels, and other devices. | Industrial equipment | |

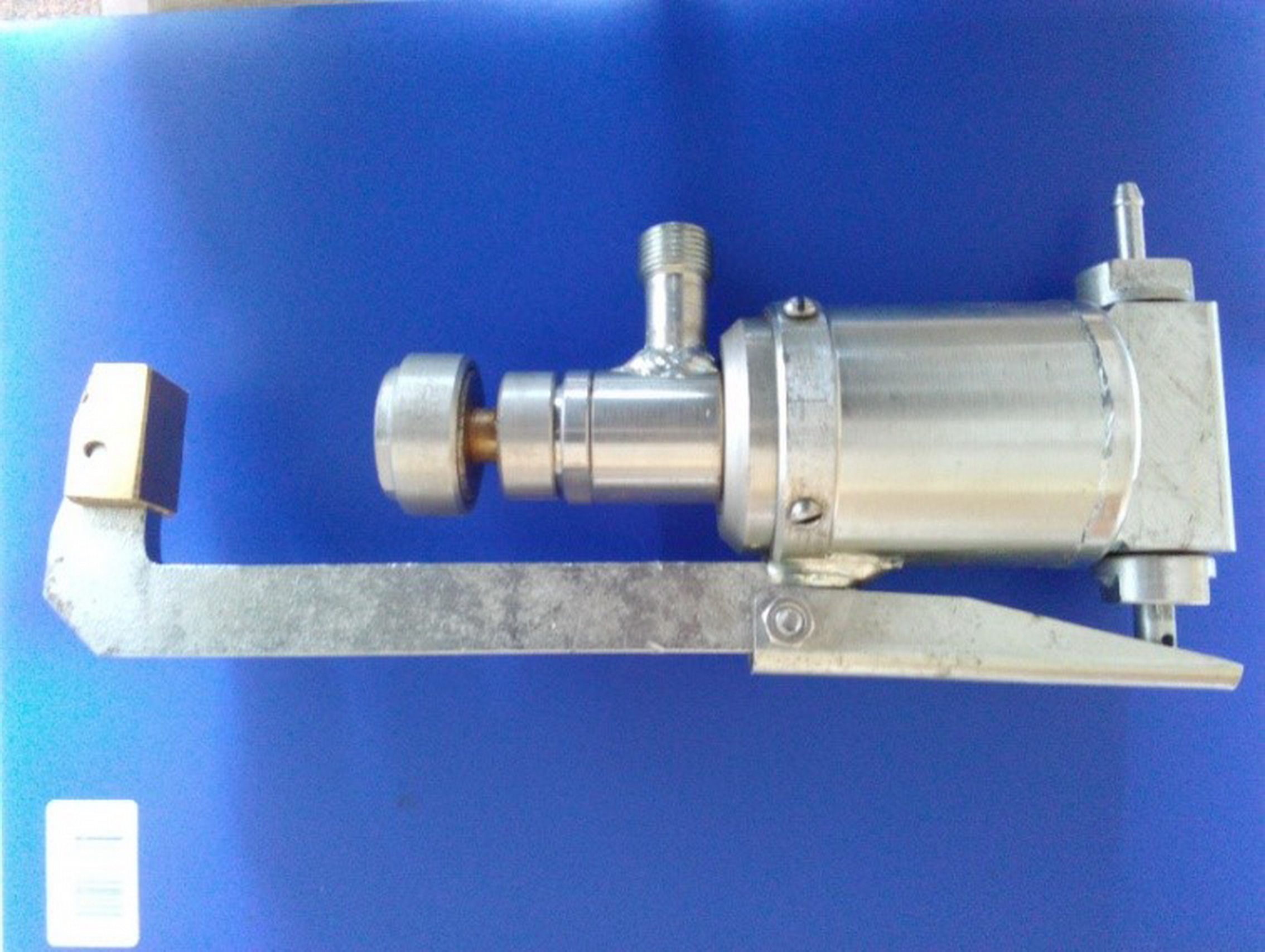

| Test bench for safety valves DN 10 ... 400 MM (⅜ ... 16 ") | PURPOSE: • leak test disc and seal seat; • door tightness test; • test of performance and adjustment of working pressure. OBJECTS TO BE CHECKED: • safety valves. STORAGE TEST TYPE OF CONNECTION: * • flanges; • threaded ends; ADVANTAGES: ■ Fast clamping and centering of the valve, tested by synchronous movement of two or three clamps. ■ Sealing Valve testing is done through the hydraulic cylinder. ■ Compact size fixing device integrated stainless steel water collection tray. ■ Water-contacting participants to corrosion. ■ Equipped with accessories for sealing adapters for each DN and a set of spare parts. | Industrial equipment | |

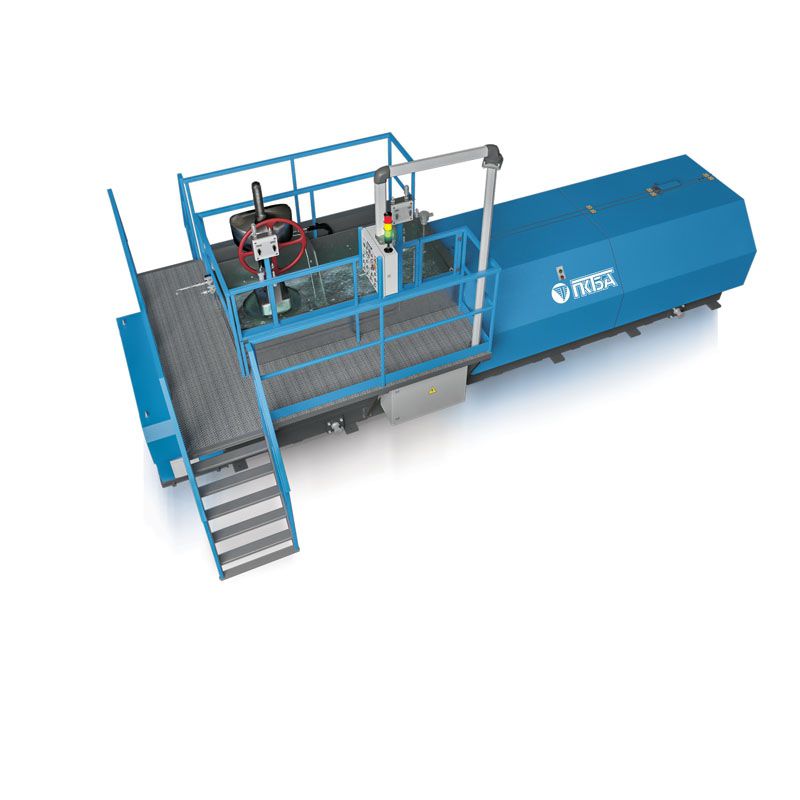

| TEST BENCHES FOR SHUT OFF VALVES DN 10...800 MM | PURPOSE:. testing the valve's body for strength and density;. gate tightness tests;. environmental leakage tests (including gland seals);. operation test;. pressure safety valves gate tightness test;. pressure safety valves operation tests.TESTED ITEMS:. gate valves;. ball valves;. stop valves (globe valves);. check valves;. butterfly gates;. plug valves.TESTED UNIT CONNECTION TYPE:. flanged (according ASME B 16.5, GOST 12815 etc.);. welded ends (according ASME B 16.25, GOST, etc.);. threaded-end;*. true union.*ADVANTAGES:-Clamping of tested valve provided by hydraulic cylinder, optionally test bench canbe equipped with proportional clamping control system, which excluding axialcompression applied to the valve body during clamping by hydraulic cylinder,during high pressure testing.*- The two-sided gate sealing during tests do not require the tested valverearrangement, which significantly reduces the test time.- The bench is equipped with the water-collection tray with stainless steel tank.*- The test preparation time is significantly reduced by using the high-pressure fastcoupling hoses.- The bench is quickly adjusted to face-to-face dimensions of valve by using theelectrically driven cross-head.-The patented design of the self-sealing adapters exclude axial compressionduring the tests, which ensures the test reliability, protects the valves againstdeformation, and extends the valve life.*- All water-wetted parts are corrosion-proof.- The bench can be equipped with replaceable sealing adapters.*- Increased-diameter hoses reduce the time of the valve filling with the test medium.-Turning upper cross-head is used to simplify the valve installation procedurebefore testing.- The test preparation time is significantly reduced by using the high-pressurequick-connect hoses.- Fast clamping and centering of the tested valve is ensured due to synchronizedtravel of the straps.- Test bench allows visual detection of seat leakage point. | Industrial equipment | |

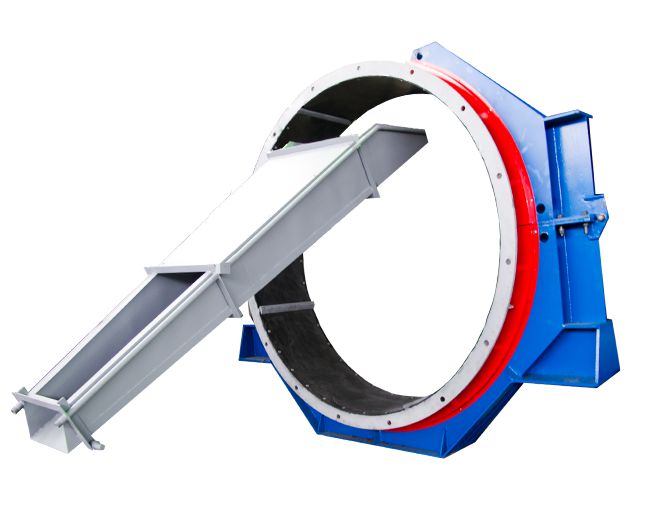

| TEST BENCHES FOR SHUT OFF VALVES DN 400...1400 MM | PURPOSE:• testing of the body part materials for strength and density (shell test);• gate tightness tests (leakage test);• environmental leakage tests (including gland seals), backseat test;• operation test (functional test).TESTED ITEMS:• gate valves;• ball valves;• butterfly valves;• check valves;• plug valves.TESTED UNIT CONNECTION TYPE:• flanged (according ASME B 16.5, ASME B 16.47,GOST 12815 etc.);• welded ends (according ASME B 16.25, GOST, etc.);*• set of sealing adapters available.*ADVANTAGES:- Clamping of tested valve provided by hydraulic cylinder,optionally test bench can be equipped with proportionalclamping control system, which excluding axialcompression applied to the valve body during clampingby hydraulic cylinder, during high pressure testing.*- Clamping unit can be provided with radial sealing type orself-sealing adapters.*- The two-sided gate sealing during tests do not require thetested valve rearrangement, which significantly reducesthe test time.- The bench is equipped with a special system for airremoval from the tested valve, which improves safety,productivity, reliability of the obtained data, and obviatesthe need for additional air drain.*-The bench is equipped with the water-collection tray withstainless steel tank.*– The test preparation time is significantly reduced by usingthe high-pressure quick-connect hoses.-The bench is quickly adjusted to face-to-face dimensionsof valve by using the hydraulically or electrically drivencross-head.- The patented design of the self-sealing adaptersexclude axial compression during the tests, whichensures the test reliability, protects the valves againstdeformation, and extends the valve life.*- All water-wetted parts are corrosion-proof.- The bench can be equipped with replaceable sealingadapters.*- Increased-diameter hoses reduce the time of the valvefilling with the test medium.- Test-bench can be equipped with valve lifting platformsfor valve positioning and support during testing.* | Industrial equipment | |

| Stands FOR TESTING VALVES DN 10 ... 400 MM (⅜ ... 16 ") | PURPOSE: • testing the body valve for strength and tightness; • door tightness tested; • environmental testing for leaks (including glands, seals); • performance check; • pressure of the valves of the safety gate tightness test; • pressure of safety valves tested. OBJECTS WHICH ARE CHECKED: • gate valves, • ball valves; • stop valves (valves); • check valves; • butterfly doors; • rotary plugs; • safety valves. CHECKING THE CONNECTION OF THE DEVICE TYPE: • flanged (according to ASME B 16.5, GOST 12815, etc.); • soldier ends (in accordance with ASME B 16.25, GOST, etc.). ADVANTAGES: ■ Valve fastening tested, presented on a hydraulic cylinder, separately on the test bench can be equipped with a proportional control system, which, with the exception of axial compression, which is used in the valve body, during fastening of the hydraulic cylinder, during high pressure testing. * ■ Both sides of the door seal do not need to test the reversing valve during testing, which greatly shortens the testing time. ■ The bank is equipped with water, a collection tray. * ■ The dough preparation time is significantly reduced due to the use of high pressure quick-connect hoses. ■ Bank adjusted quickly, face-to-face valve sizes using an electric cross-head actuator. ■ Patented design of auto-sealing adapters to eliminate axial compression during testing, which provides reliability testing, protects the valve from deformation and prolongs valve life. * ■ Water-contacting participants are corrosive. ■ The bank can be equipped with replaceable seal adapters. * ■ Increasing the diameter of the hoses shorten the filling time of the valve using a test. ■ A fold-down top of the cross-head is used to simplify the valve installation procedure before testing. Dough preparation time is greatly reduced due to the use of high pressure quick connect hoses. ■ Fast fastening and centering test of the valve is ensured thanks to the synchronized travel of the guy wires. ■ Valve test, fastening technical is used to provide visual control of vanishing points. ■ It is possible to carry out tests for the door tightness of flange valves with vertical and horizontal axes of the position of the main branch of the pipe with the order of a visual inspection of the damper. | Industrial equipment | |

| Stands FOR TESTING VALVES DN 15 ... 600 MM (⅔ .... 24 ") | PURPOSE: • immersion testing of gas pipelines, valves; • testing of body parts made of materials for strength and density; • door tightness tested; • Environmental testing for leaks (including glands, seals). OBJECTS WHICH ARE CHECKED: valves • cryogenic; • gate valves, • ball valves; • butterfly valves; • check valves; • rotary plugs. CHECKING THE CONNECTION OF THE DEVICE TYPE: • flanged (according to the standards ASME B 16.5, ASME B 16.47, GOST 12815, etc.); • soldier ends (in accordance with ASME B 16.25, GOST, etc.); * • elements, ends, small size of valves; * • set for sealing all available adapters. * ADVANTAGES: ■ Valve fastening tested, presented on a hydraulic cylinder, separately on the test bench can be equipped with a proportional control system, which, with the exception of axial compression, which is applied in the valve body, during the fastening of the hydraulic cylinder, during high pressure testing. * ■ The clamping block can be equipped with a shutter, radial type or auto -Seal adapters. * ■ Both sides of the door seal during testing do not require testing of the flap valve, which greatly reduces the testing time. ■ The bank is equipped with a special system for removing air. The valve is proven to increase safety, productivity, the reliability of the data obtained and eliminates the need for air by an additional drain. * ■ The bank is equipped with water, the tray for collecting the tank is made of stainless steel. * – due to the use of high pressure quick connect hoses. ■ Bank adjusts quickly, face-to-face valve sizes using hydraulically or electrically operated cross-head overhead. ■ Patented design of auto-sealing adapters to eliminate axial compression during testing, which provides reliability testing, protects the valve from deformation and prolongs valve life. * ■ Water-contacting participants are corrosive. ■ The bank can be equipped with replaceable seal adapters. * ■ Increasing the diameter of the hoses shorten the filling time of the valve using a test. ■ Testing in the Bank can be equipped with a valve platforms lifting valve position and support during the test. * | Industrial equipment | |

| UNO SOLDERING / OVERLAPPING MACHINES, PIPES, VALVES, PARTS | PURPOSE: • Automated hardening / cover of conveyor sides and elements of diameter from 50 to 1200 mm (2 … 48 ") with or without swing electrodes with submerged arc welding process or in shielded gases (MIG / MAG processes) with wire. ADVANTAGES: The machine is equipped with a forced cooling of the weld block and a set of water-cooled welding head. Electrode pendulum mechanism allows to increase the width of the overlapping seam up to 60 mm (2. "). The advanced construction rotator allows overlapping workpieces in three coordinates (tilt angle and position along the x and y axes). The machine control system is based on an industrial controller, hence allows the operator to set the hardfacing / overlay parameters (vibration amplitude, amplitude, speed, faceplate revolutions, and seam length) via the touch screen on the control panel. ■ The device is equipped with a remote control. ■ Time to release "gas" flow – no more than 10 minutes. ■ Spare parts kit includes a set of tools, wear parts and a first aid kit. ■ Welding of the backlight area. the circumference of the seal of the weld is in the horizontal plane (overlapping seal rings, welding flanges). * ■ The machine achieves a surface hardness of 60 HRC. ** | Industrial equipment | |

| SPSH PIPE GRINDING AND LAINING MACHINES, VALVES DN 50 ... 1000 MM | PURPOSE: • The machines are designed for grinding and lapping the plane of the sealing surfaces of the body and wedges of valves, rear-view mirrors and coils, shut-off valves (valves), safety valves and other flat surfaces. VALVE TYPE: • gate valves; • valve; • safety valve. * VALVE DN: Hard disks: • SPSH-600-N: DN 50 … 600 mm (2 … 24 "); • SPSH-1000-N: DN 300 … 1000 mm (12 … 40 "). Block with two tables and tilted: • SPSH-600-NN: DN 50 … 600 mm (2 … 24 "). Base unit table: • SPSH-300-NN: DN 15 … 300 mm (½ …12"); • SPSH-300-VV: DN 8 … 300 mm (0.3 … 12 "). | Industrial equipment | |

| RMR WORKSTATION FOR CRANES, MOUNTING / DISMANTLING | Industrial equipment | ||

| PORTABLE MACHINES FOR REPAIR OF GATE VALVES | PURPOSE:. portable machine is designed for grinding and lapping thesealing surfaces of the gate valve trim and wedges withouttheir dismantling from the pipeline.MACHINED-SURFACE TYPES:. sealing surfaces of the gate valve trim and wedges.DN OF VALVE:. 50…250 mm (PUR-1);. 200…600 mm (PUR-2). Тех. спецификации COMPLETE SET:• portable unit;• professional pneumatic (Atlas Copco) and/or electric (Bosch) drives;*• device for mounting on the middle flange;• device for machining the gate valve wedges;• replaceable grinding and lapping discs;• a set of self-adhesive grinding wheels;• air preparation unit with a sleeve for compressed air supply;• plastic case;• set of spindles with the abrasive wheels based on electrocorundum (PUR-1, PUR-2);• set of spindles coated with the boron nitride (PUR-1, PUR-2). | Industrial equipment | |

| MOBILE WORKSHOPS | PURPOSE: • modular structure of container workshop solutions allows its adoption in accordance with the requirements of customers and climatic conditions of use. Our range of models addresses the most critical valve problems, high pressure repairs for testing, calibration and maintenance of various valve types. OBJECTS WHICH ARE CHECKED: • gate valves, • ball valves; • shut-off valves; • check valves; • safety valves; • control valves. MOBILE WORKSHOP VERSIONS: • PKTBA-MK-1 mobile workshop test valve. • PKTBA-MK-2 mobile valve, test and repair. • PKTBA-MK-3 for mobile fittings and workshops. | Industrial equipment | |

| Transformer sleepers ШТ27, ШТ12 | We sell sleepers for rolling tracks of transformers: ШТ12 and ШТ27 ШТ27, 250х300х2700, drawing 3.407.1-157.1-18, weight of one tie is 510 kg, at a price of 4100 rubles / piece. ШТ12, 200х200х1200, drawing 3.407.1-157.1-18, weight of one sleeper 225 kg, at a price of 2100 rubles / piece. Transformer sleepers SHT-27 and SHT-12 produced by us will be indispensable in any construction of rail tracks for rolling transformers. And their reliability, the price favorable from many competitors and the location of the warehouse in the very center of Russia will become for you the main decisive argument when purchasing sleepers ShT-27, ShT-12 from VolgaSpetsProfil Group of Companies LLC. We also produce all fasteners for reliable fixing of rails to transformer sleepers, so those interested in our products can purchase everything in one place. Choosing us you are guaranteed to save precious time and money. It is worth noting that transformer sleepers differ in size. Dimensions of ShT-27 are 250x300x2700 mm. The weight of one product is 510.00 kg. at a price of 4100 rubles / piece Dimensions of the ShT-12 are 250x300x1200 mm. The weight of one product is 225.00 kg. at the price of 2,100 rubles / piece. Those. specifications Used in the construction of rail tracks for rolling transformers | Industrial equipment | |

| MOD-1M1 | Jigging machines MOD-1M1 are designed for gravitational enrichment in an aqueous medium of base and alluvial ores of non-ferrous metals, diamonds, as well as other ore materials by the method of jigging. , tin and at the plants of ferrous metallurgy for the production of iron ore and ferrochromium concentrates. In the company "Mining Machines" JSC, you can buy a jigging machine that is suitable specifically for your beneficiation technology. We are waiting for questions about the selection and purchase of mining and processing equipment by phone +7 (391) 219 29 03 and by mail [email protected] Tech. specifications Productivity for the initial product, t / h, no more than 10 Working area of sieves, m 21 Number of chambers, pcs 2 Length of the cones stroke, mm 40 Stroke frequency of the cones, min-1 within 130-350 Feed size, mm, no more than 15 Installed power, kW 1.1 Overall dimensions, mm, not more than length 20 40 Height 216095 6 , kg 905 | Industrial equipment | |

| Electric drilling rig SBSh-250 MNA-32. | We will select a modification of the SBSh-250 drilling rig according to the technical specifications of your enterprise. SBSh-250 is the best solution for drilling technological blast holes. Electric drilling rig SBSh-250 MNA-32 drills blast holes in rocks with a strength of 6-18 units. on the scale of prof. Protodyakonov in open pit mining. The machine consists of a caterpillar track and an engine room with a driver's cab and a mast mounted on it. Links, wheels and rollers are cast from high-alloy steel with heat treatment using a special technology. The tracks are tensioned by a double-acting hydraulic cylinder. The inclined surface of the frame and the installation of supporting rollers on the cantilever axle prevent them from slugging and sticking of soil when working in wet conditions. Bearings filled with grease for a lifetime are used in the bearing units of the caterpillar track. , sheathed with a metal sheet. Inside is located: a compressor unit; an oil station, the main working elements of which are: the main pump with adjustable performance, which ensures the creation of a given force on the drilling rod and other operations; auxiliary pump – provides quick lowering and lifting of the drill string when building up or disassembling it; rotator and travel drives, electrical cabinets and other equipment. Two Schneider Elektric frequency converters provide control of asynchronous travel motors when moving the SBSH-250 drilling rig. In the process of drilling, the converters switch to control the asynchronous electric motors of the rotator and the hydraulic pump. As an option, the machine can be equipped with a dry dust suppression system, consisting of a dust extraction chamber, coarse cyclones, fine filters and a suction fan. Manufactured with insulated walls, ceiling and floor, it creates comfortable conditions for service personnel. To reduce vibration when drilling hard rock, the cabin can be installed on jacks and separated from the engine room. For the drilling rig operator there is a vibration-proof seat adjustable in height, to control the drilling process and control the operation of the basic units of the drilling rig, there are conveniently located consoles with indication of drilling parameters and the state of the working Doors with reliable locks and seals ensure tightness, and the air conditioner, supplying purified air, creates excess pressure. At subzero temperatures, the heater turns on. Conveniently located windows provide the driver with a good view of the working mechanisms. Bored mast The SBSh-250MNA-32 mast is a spatial structure, which is fastened to supports through sliding bearings. Installation of the mast in the working or transport position is carried out by two hydraulic cylinders. Fastening it to the working position is done with two clamps. Those. specifications Execution, mm -37 -37-02 -37-03 -37-04 -37-05 -37-06 -37-07 Borehole diameter, mm 250 250 250 250 250 190 250 Rod length m 8.2 8.2 8.2 8.2 8.2 11.4 8.2 Number of rods 4 6 (2 separators) 6 (2 separators) 4 4 5 4 Drilling depth, m 32 47 47 32 32 55 32 Dust suppression method wet wet wet wet wet wet wet Supply voltage, V 380 380 380 380 6000 380 6000 Total set. power, kW 460 460 490 490 490 500 500 Rotator motor power, kW 90 DC current 90 DC current 90 a.c. current with frequency adjustable 90 perm. current with frequency adjustable 90 perm. current with frequency adjustable 120 120 Speed of lowering / lifting of the drill. projectile, m / min. 25/25 25/25 25/25 25/25 25/25 25/25 25/25 Feed rate of the drillstring to the bottom, m / min. 0… 3 0… 3 0… 3 0… 3 0… 3 0… 3 0… 3 Compressor capacity, m3 / min. 32 32 32 32 32 32 32 Rot. Boer. speed rpm 0… 120 0… 120 0… 120 0… 120 0… 120 0… 120 0… 120 Motor power. stroke drive, kW 2х35 DC adjustable speed 2х35 DC adjustable speed 2х45 AC adjustable speed (frequency control) 2×45 AC speed control (frequency control) 2×45 AC speed control (frequency control) 2×50 DC variable speed 2×50 DC variable speed Travel speed, km / h 0-1.3 0-1.3 0-1.8 0-1.8 0-1.8 0-1.8 0-1.8 Max overcoming angle, deg. 12 12 12 12 12 12 12 Weight, kg 80,000 80,000 80,000 80,000 80,000 90,000 85,000 Overall dimensions with the mast raised, m length 10.5 10.5 10.5 10.5 10.5 9.9 10.5 width 5.7 5.7 5.7 5.7 6.1 6 5.7 height 16.2 16.2 16.2 16.2 16.2 19.8 16.2 Overall dimensions with the mast lowered, m length 15.6 15 , 6 15.6 15.6 15.6 19.2 15.6 width 5.7 5.7 5.7 5.7 6.1 6 5.7 height 6.6 7.1 7.1 6.6 6.6 7.3 6.6 | Industrial equipment | |

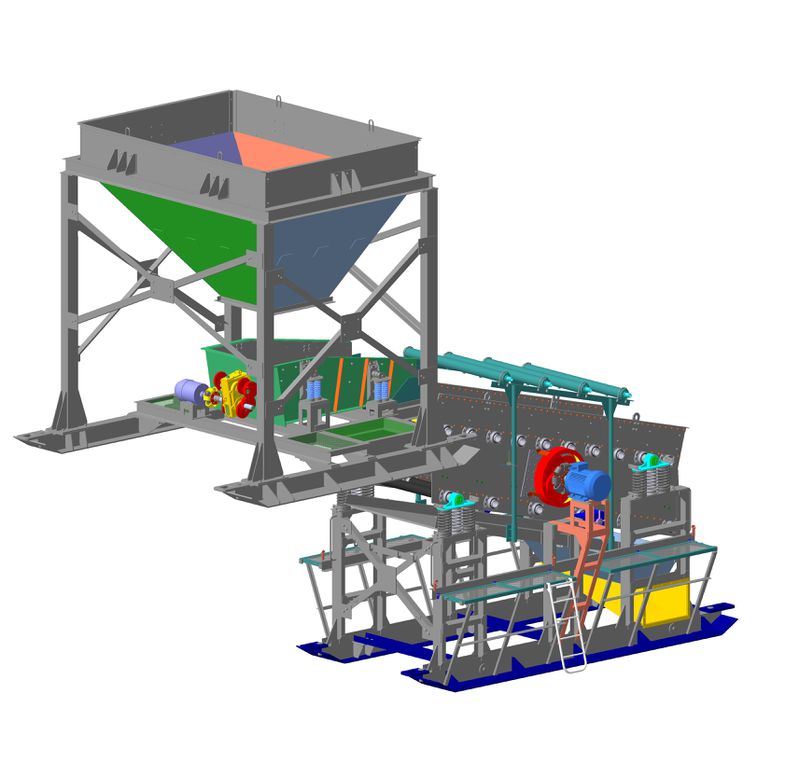

| Washing and sorting complex PSK-52 | The washing and sorting complex (prompribor) is designed for the development of small deposits of gold and effelous dumps of technogenic placers. The washing and sorting complex PSK-52 is a modular structure consisting of two independent units: a screening module and a power module, with an individual drive for each module. Both units of the industrial device can work autonomously, in the PSK unit they are installed in cascade relative to each other. The screening module consists of a screen, a mobile frame of the "sleigh" type with folding service platforms, ladders, a funnel for collecting and removing the undersize product, an irrigation system for the upper tier (irrigation of the lower of tiers is carried out through the built-in screening irrigation system – if necessary). Washing and sorting complex PSK-52 includes: Power module based on a vibrating bunker feeder PV-PBR-1.4 / 2.7 equipped with a bunker with a capacity of 18 m3. on the basis of a heavy-duty inertial screen GIT-52MB with service platforms (the type of screening surfaces is specified by the customer). Washing and sorting complexes, depending on the tasks and characteristics of the gold washing area, can be manufactured on the basis of the following screens: GIT-41AXGIT-53PGIT-52MMGIT-32GIT- 62MGIT-62EGIT-42MGIT-62MEGIT-63VGIT-51MGIT-63VGST-42GIT-52MGIT-71MGST-72GIT-52MBGIT-73P Tech. specifications Technical parameters of the feeder PV-PBR-1.4 / 2.7 Indicator name Indicator Unloading lumpy (up to 500 mm) with bulk bulk weight, t / m3, up to 2.8 Chute width, mm 1400 Chute length, mm 2700 Productivity, m3 / h 50 … 400 Amplitude oscillations, 2 … 5 Frequency of oscillations, Hz * 12.2 … 16.5 Angle of vibration, degrees 20 ° Angle of inclination of the bottom of the tray, degrees 10 ° Drive power, kW 11 Engine, type AIR160S6 Speed, min 970 Overall dimensions, mm – length 3180 – width 2190-height 950 Mass of oscillating parts, kg 1950 Technical parameters of the screen GIT-52 Indicator name Indicator Dimensions of the sieving surface, mm – length 1750 – width 5000 Number of tiers of sieves, pcs 2 Angle of inclination of sifting surfaces, degrees 15-30 ° Vibration amplitude, mm, within 6.0-9.6 Frequency of oscillations, min-1730 pieces, grain mm, no more than 400 Power supply capacity, m3 / hour, within 350 … 800 Rated motor power, kW 22 Overall dimensions of the vibrating part of the screen, mm: – length 5250 – width 2390 – height from 1713 Mass of the vibrating part of the screen (without sieving surfaces and fastening elements), kg, within 4980 ± 20 Mass of spare parts, kg 355 ± 10 | Industrial equipment | |

| Feeder PK-1,2-10 | Oscillating feeders of the PK-1,2-10 type are designed for uniform delivery of non-sticky bulk materials with a bulk density of bulk cargo up to 1200 kg / m3 and a size of no more than half the width of the tray from bins, funnels and other containers into technological machines or transporting devices. -1.2-10 is used in the coal, metallurgical industry, at the enterprises of the building materials industry. Those. specifications Indicator name Indicator Productivity, cubic meter / hour (t / h) 420 (500) Tray width, mm1000 Tray length, mm 2060 Tray travel, mm, no more than 200 Rated engine power, kW, no more than 7.5 Overall dimensions, mm, no more – length 4000- width 1750 – height 1500 Weight, kg, no more than 1900 | Industrial equipment | |

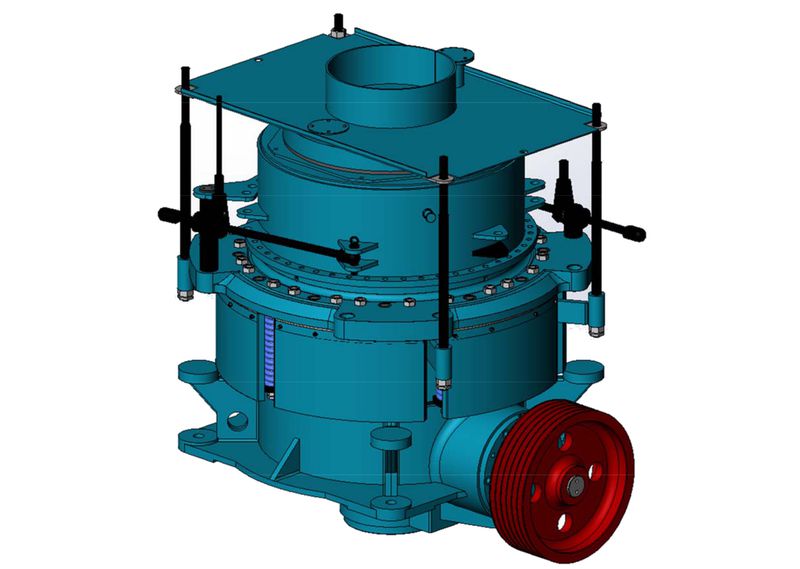

| Cone crusher KMD-900 | The purpose of the KMD-900 cone crusher is fine crushing of solid and high-strength rocks. The size of the loaded pieces of material is 40-80 mm, and the maximum size of the pieces at the exit is from 8 to 15 mm. The main “consumers” of crushers of the KMD-900 model are mining and processing enterprises, for example, those engaged in the processing of iron ores, gold mining enterprises. Cone crushers KMD-900 can be built into automated technological lines at the second and third stages of crushing. The company JSC "Mining Machines" offers to buy cone crushers of medium and fine crushing. KSD cone crusher. KMD cone crusher. Spare parts and components. Those. specifications Standard size KMD-900 Size of a piece of raw material, mm 40-80 Width of discharge slot, mm 8-15 Productivity, m3 / hour 30-45 Drive power, kW75 Weight, kg11700 Overall dimensions (L x b x h), no more than, mm 2300x2300x1960 | Industrial equipment | |

| Cone crusher KMD-900 | The purpose of the KMD-900 cone crusher is fine crushing of solid and high-strength rocks. The size of the loaded pieces of material is 40-80 mm, and the maximum size of the pieces at the exit is from 8 to 15 mm. The main “consumers” of crushers of the KMD-900 model are mining and processing enterprises, for example, those engaged in the processing of iron ores, gold mining enterprises. Cone crushers KMD-900 can be built into automated technological lines at the second and third stages of crushing. The company JSC "Mining Machines" offers to buy cone crushers of medium and fine crushing. KSD cone crusher. KMD cone crusher. Spare parts and components. Those. specifications Standard size KMD-900 Size of a piece of raw material, mm 40-80 Width of discharge slot, mm 8-15 Productivity, m3 / hour 30-45 Drive power, kW75 Weight, kg11700 Overall dimensions (L x b x h), no more than, mm 2300x2300x1960 | Industrial equipment | |

| Plasma universal installation Model UPU-10 | Designed for the application of metal, ceramic powder materials on the surface of products by plasma spraying and allows you to apply wear-resistant, corrosion-resistant, frictional, insulating and other special coatings simultaneously from two powder dispensers. 40 ". Powder supply system, consisting of two dispensers. Gas supply unit. Autonomous cooling system. Modern automated control and monitoring system of the plasma spraying process based on a programmable controller of the DirectLogic family. Upgraded rectifier model" VPN-650. UPU-10 is built on the basis of a personal computer (upper level) (OPTIONAL) and an industrial programmable logic controller D0-06DR (lower level). | Industrial equipment | |

| Installation for coating APN-250 | The APN-250 installation is intended for applying protective, heat-resistant, erosion-resistant, wear-resistant and other types of coatings on products with an axis of rotation, by plasma method in a vacuum, repairing parts with complete removal of the previously applied coating from the treated surface and re-coating. | Industrial equipment | |

| Vacuum melting unit Models: UPPF-U | Vacuum induction unit "UPPF-U" is designed for casting products with a polycrystalline structure from heat-resistant alloys in batch production and for testing complex technologies in pilot production. maintenance, safety requirements, quality of smelted metal, reliability with a load factor of 0.9-0.95. – Reducing operating costs (consumption of electricity, water, air per 1 kg of liquid metal). | Industrial equipment | |

| Installation of electron beam welding ELU-20R | Installation of electron beam welding "ELU-20R" is intended for the manufacture of assembly units of products from stainless steels and titanium alloys. This installation is intended for precision electron beam welding of circular, circumferential, longitudinal seams on cylindrical and tapered products made of stainless steel, heat-resistant and titanium alloys. Welding is carried out from a computer-controlled ELA 60 / 60VM power unit. | Industrial equipment | |

| Installation for manual arc welding in a controlled atmosphere model: USKS-21 | Designed for manual arc welding in a controlled atmosphere of parts and assembly units made of titanium alloys and other active metals. The working process is carried out using a manual welding torch in a sealed chamber with a controlled argon atmosphere. During the welding process, the content of impurities in the working environment is controlled and the working environment is purified from hydrogen and water impurities. | Industrial equipment | |

| Installation for welding in a controlled environment model: USKS-25 | Installation "USKS-25" is designed for electric arc welding of chemically active metals and alloys based on them in an inert environment (argon with oxygen impurity content – no more than 0.0003%, nitrogen – no more than 0.01%, hydrogen – no more than 0.006 %, water vapor – no more than 0.004%) The installation includes several systems: machine, vacuum, power, control, water cooling, pneumatic. | Industrial equipment | |

| Vacuum thermal furnace PVV-1300 | Vacuum thermal furnace "PVV-1300" is designed for homogenization of parts and disks made of heat-resistant alloys, hardening, brazing, tempering and annealing after heat treatment. The work of the furnace consists in heating the workpiece to be processed in vacuum to a certain temperature, holding it at this temperature, moving the workpiece into the lower chamber and cooling it in an inert gas. Structurally, the furnace is made in the form of two vacuum chambers: heating and cooling. | Industrial equipment | |

| Installation for arc welding in a controlled environment model: USKS-26 | Installation "USKS-26" is designed for automatic arc welding with a nonconsumable (tungsten) electrode in a controlled environment of body products made of chemically active metals and alloys based on them, placed on the faceplate of the rotator. – Argon supply system – Cylinder fastening – Pneumatic system – Welding source – Control cabinet – Operator panel – Lifting mechanism – Base – Electrical wiring | Industrial equipment | |

| Installation of centrifugal spraying UCRT9 | Designed to obtain metal powders of highly reactive metals, high-temperature nickel and titanium alloys by centrifugal spraying of blanks melted by a plasma heater in an inert gas environment with simultaneous transportation of the resulting powder materials into a volumetric sealed container without contact with air. | Industrial equipment | |

| Installation for welding in a controlled environment Model USKS-27 | The USKS-27 unit is designed for automatic and manual arc welding with a non-consumable electrode in a controlled environment of circular and longitudinal seams of products made of chemically active metals and alloys based on them, installed on the rotator faceplate, with or without filler wire. The maximum diameter of the welded products is 800 mm, maximum height – 800 mm, maximum weight of the welded product – 250 kg The installation allows automatic welding with a welding head of butt, tee, overlap joints of bodies of revolution with a horizontal axis of rotation at various positions of the head – from vertical to rotated at an angle of ± 45 ° from vertical. When the axis of rotation is set to a vertical position, it is possible to weld the end connections of the bodies of revolution with the vertical position of the head. The installation can be used to weld with manual welding torches for 150 A and 400 A to body parts of bends, fittings, plates, brackets, etc. In automatic mode, welding of all joints can be carried out with or without oscillation of the electrode. Welding of butt joints can be carried out with automatic maintenance of a given value of the arc gap. The USKS-27 installation is a chamber installation consisting of complexes: mechanical, vacuum, power, automatic control systems, air supply systems, cooling systems. the chamber cover, the item to be welded with accessories on the faceplate of the rotator and a mechanized welding head, two hand torches for 150 A and 400 A. | Industrial equipment | |

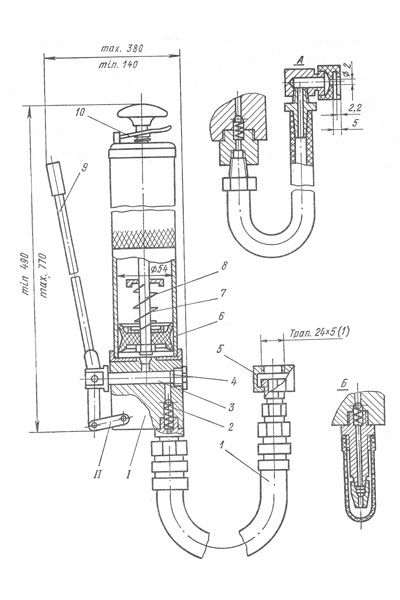

| Filling station for household cylinders 50 l for two stations (PNB-50/2) | 1.1 The station for filling cylinders PNB (hereinafter – the post) is intended for filling cylinders in accordance with GOST 15860-84 with liquefied petroleum gas (LPG) in accordance with GOST 20448-90. 1.2 The post is operated in the shops for filling cylinders of gas filling stations (GNS) and is installed in rooms of class B-1a according to PUE. The category of premises for explosion and fire hazard is A according to ONTP 24-86 “Determination of categories of premises and buildings for explosion and fire hazard”. 1.3 In terms of resistance to the effects of climatic factors of the external environment, the post is classified as UHL products, location category 4 in accordance with GOST 15150-69. Those. specifications 2. TECHNICAL CHARACTERISTICS Table 1 Name of the main parameters Value of parameters for stations PNB5 / 2; 27/2; 27/4; 50/2; 50/41 Number of filling stations, pcs 224242 Volume of processed cylinders, l 527503 Productivity, cylinders / h 80-10 260-580- 1040-5 80-104 Working pressure of LPG, MPa, not more than 1.65 Air pressure in the pneumatic system, MPa 0.65 – 0.056. Compressed air consumption, m3 / bal 0.00057 Service personnel, persons 18 Filling station – type of scales – graduation price, g RN 50 SH13TU 25-7723.000920; RP-150MGTU 25-7723.000650; | Industrial equipment | |