Machine-tool building

| Image | Name | Summary | Categories |

|---|---|---|---|

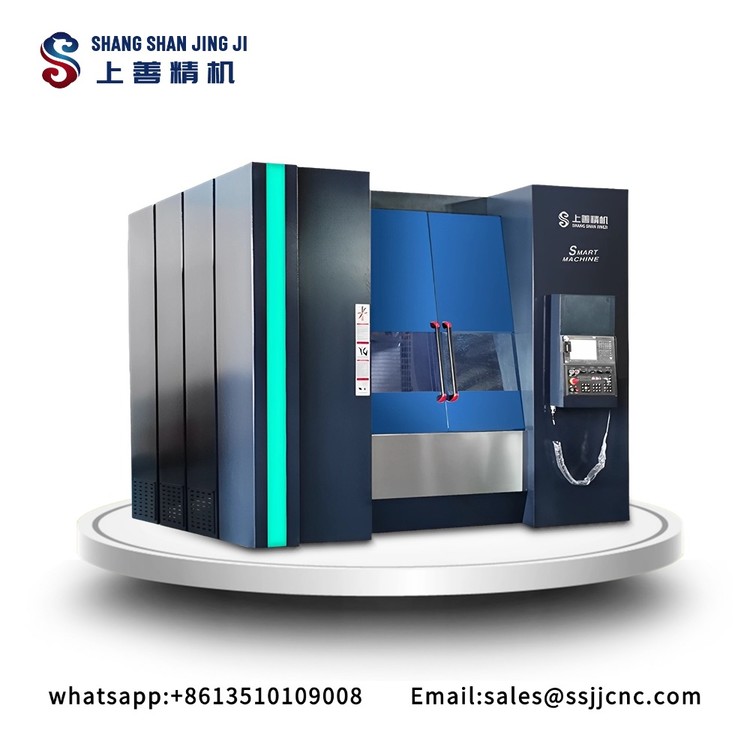

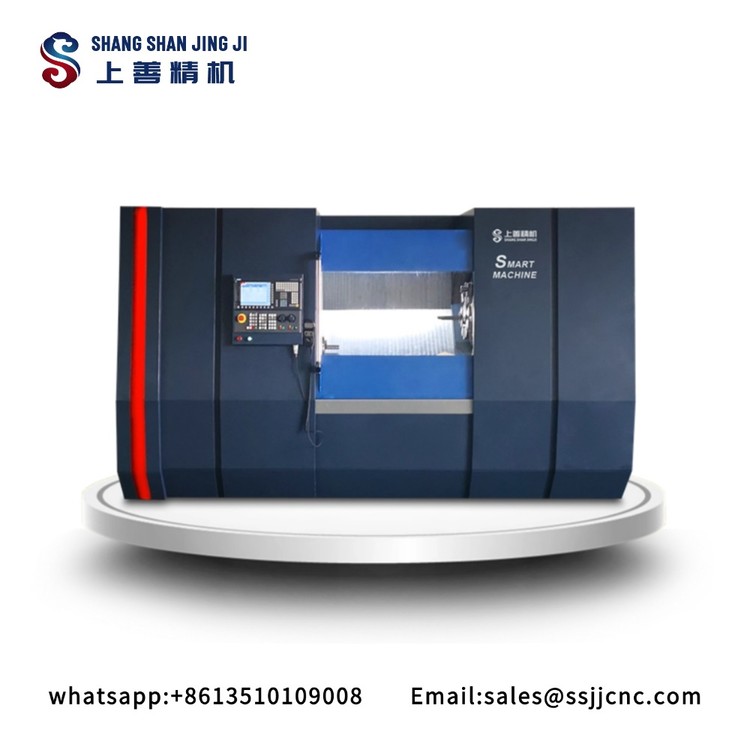

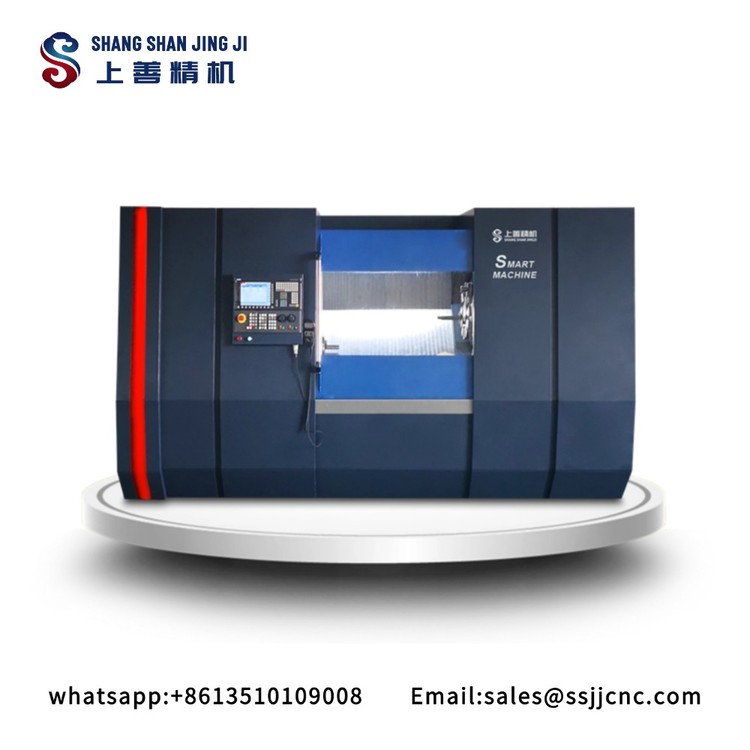

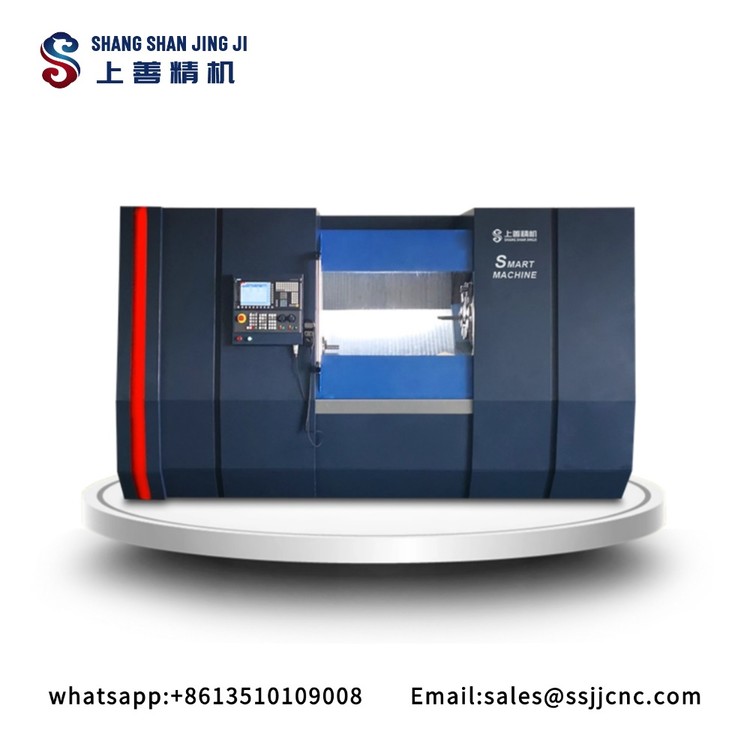

| Longmen graphite CNC milling machine Electrode machining equipment S-1800G | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Large-size graphite electrode processing machine S-500NCM | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

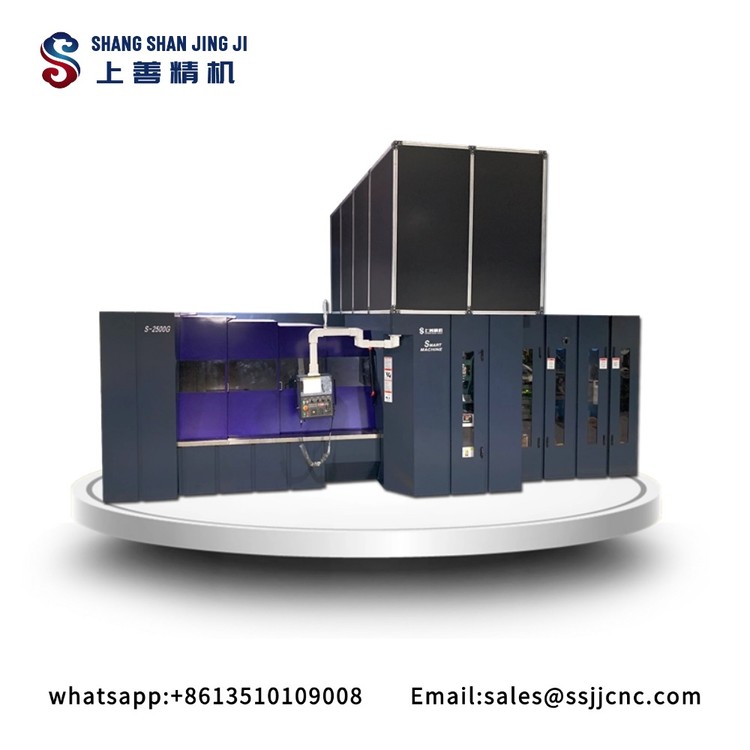

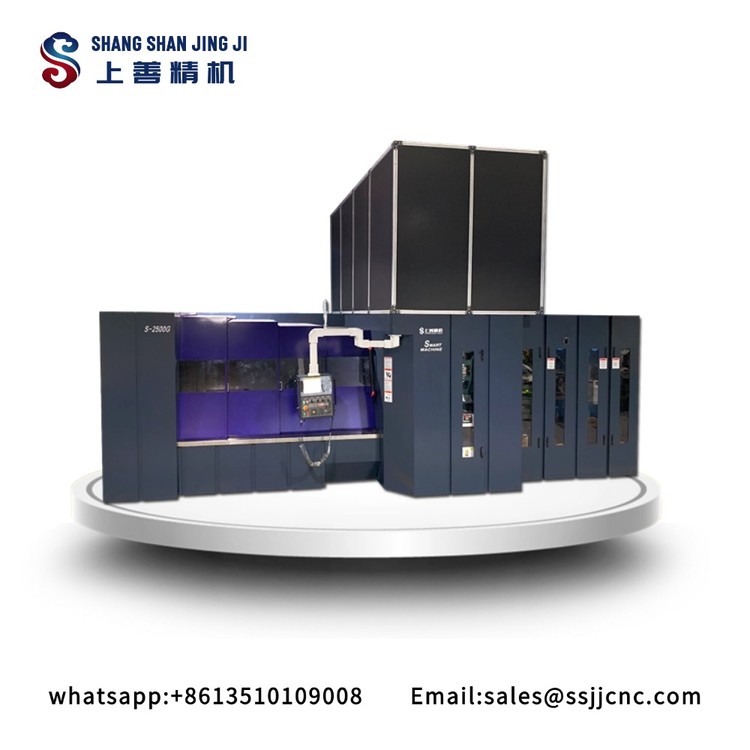

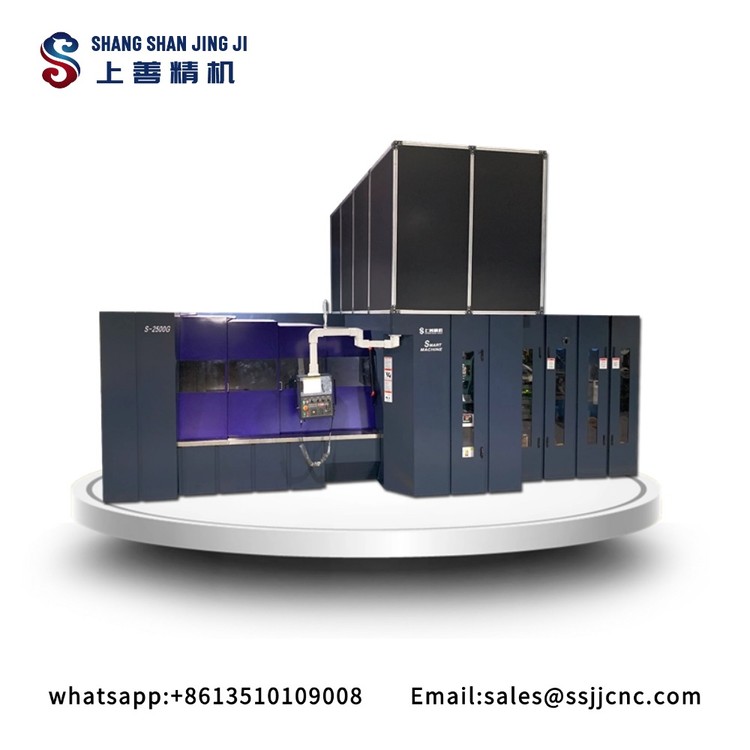

| Dry graphite processing machine tool Graphite electrode parts processing equipment S-2500G | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

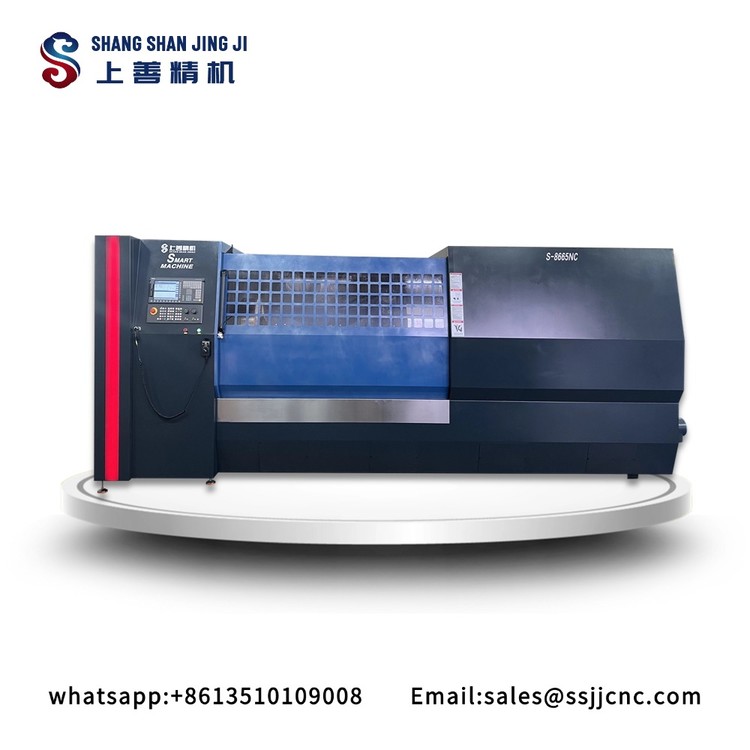

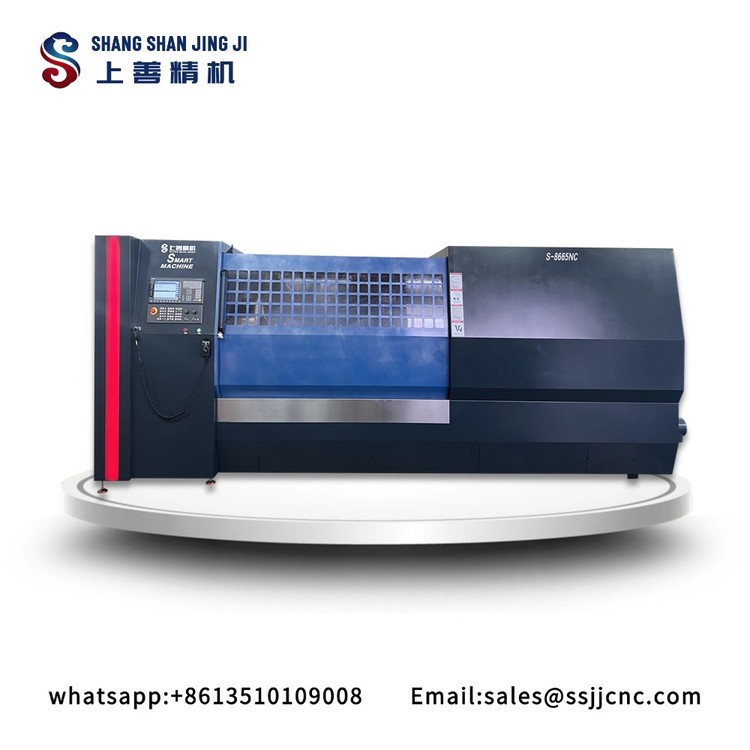

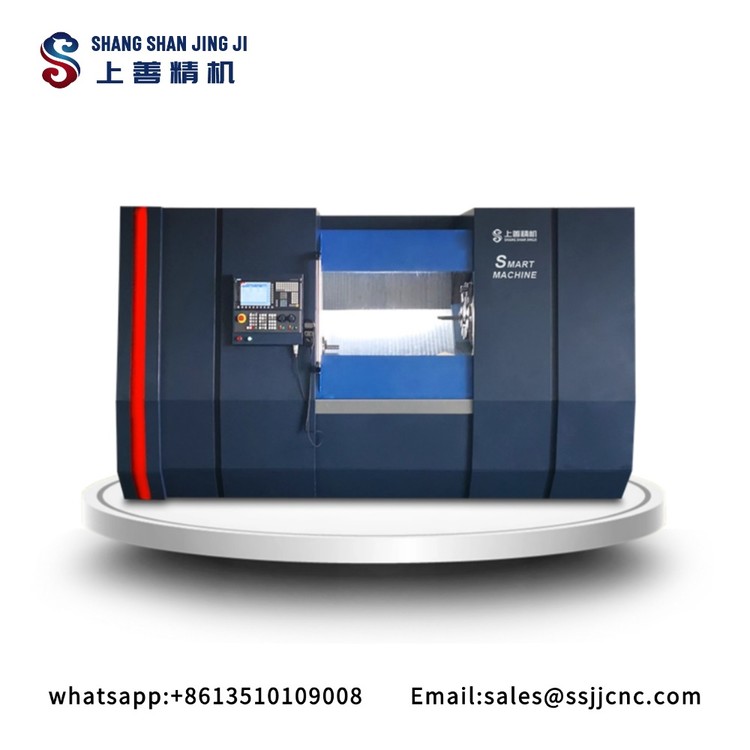

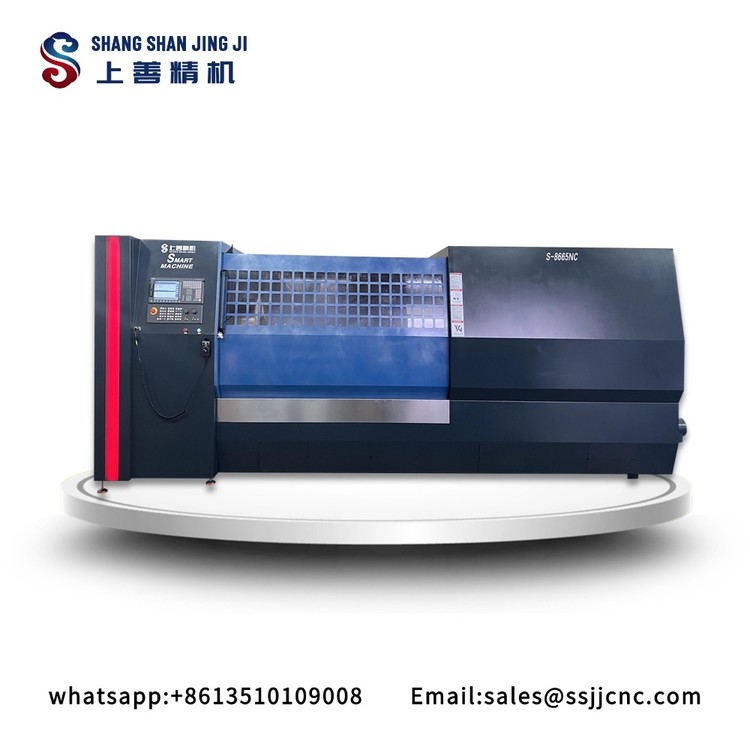

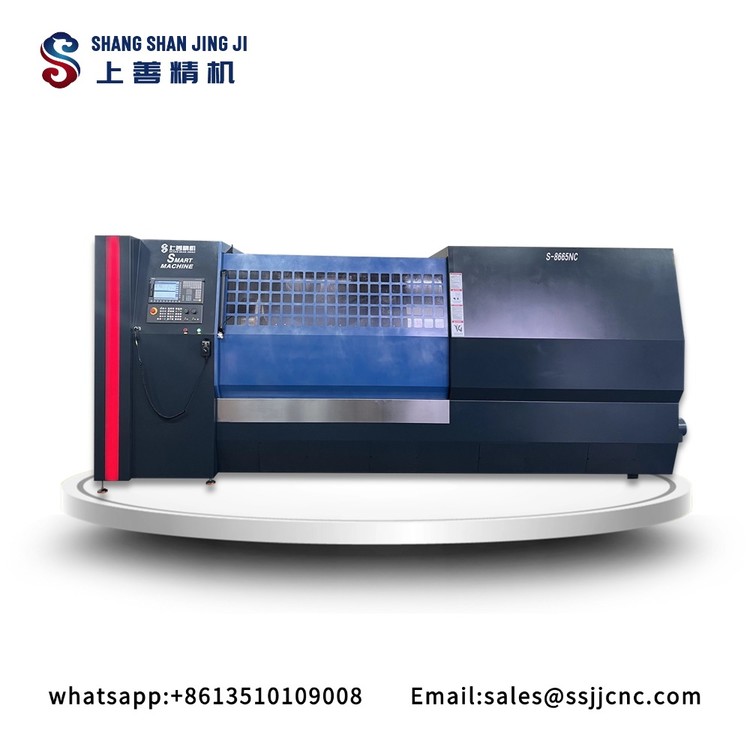

| Graphite bolt automatic processing equipment Milling machining center + CNC S-8665NC | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

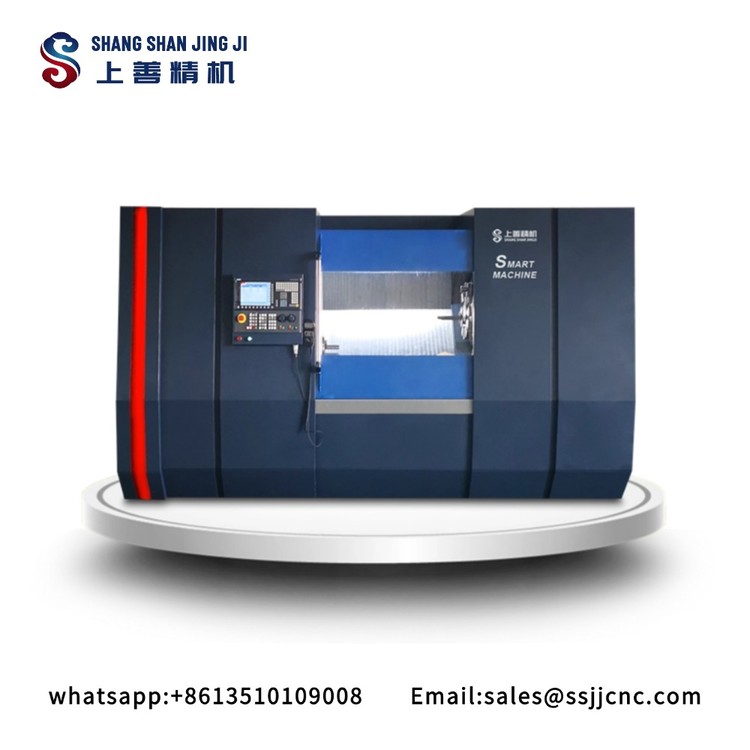

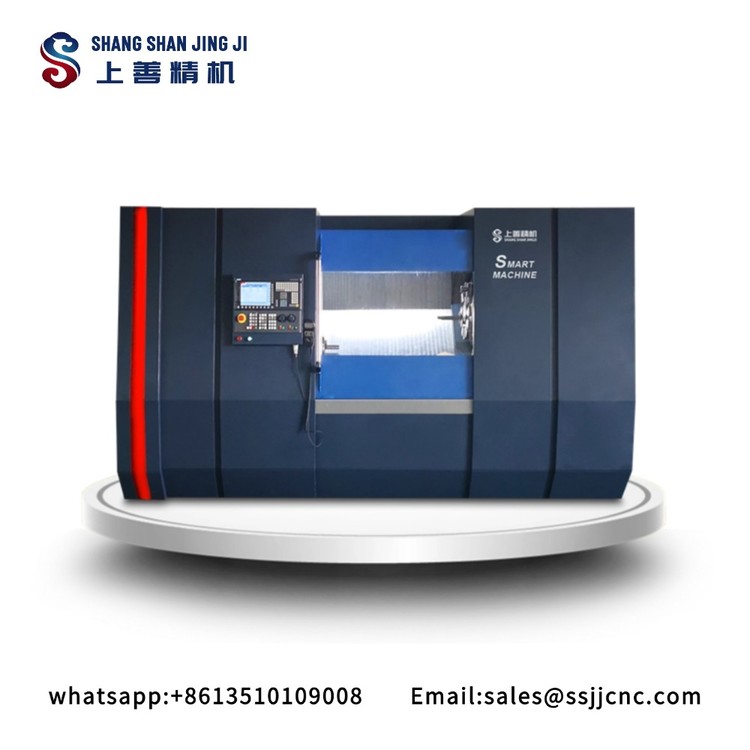

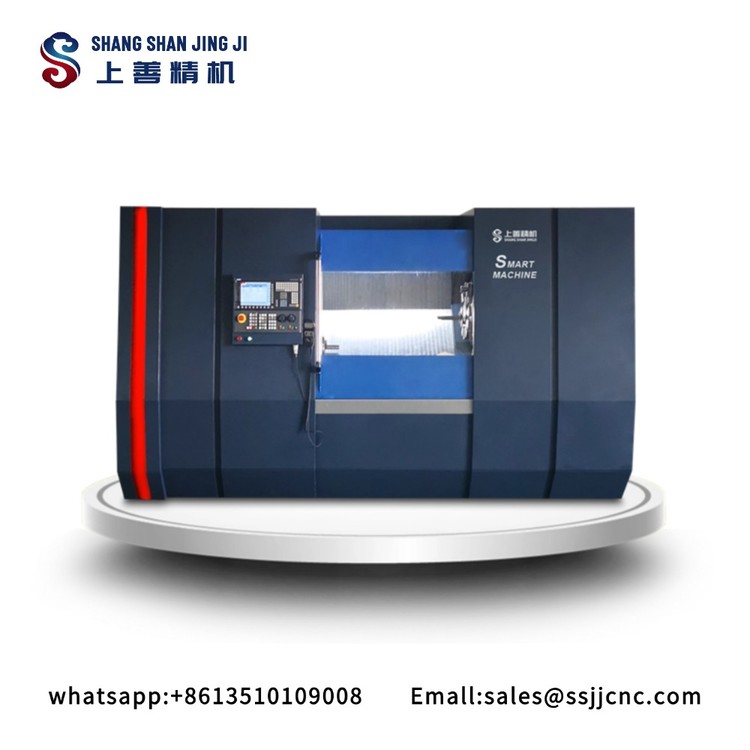

| Graphite rotor automation processing equipment CNC graphite processing machine S-960V | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| CNC precision milling machine Lathe processing graphite S-310NC | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Vertical graphite engraving machine Graphite engraving machine S-960V | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Graphite electrode connection processing lathe Graphite electrode parts processing equipment S-960V | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Computer gong graphite machine Graphite electrode connection processing lathe S-2500G | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Copper electrode precision engraving machine Graphite disc processing machine S-310NC | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| CNC milling machine machining center Graphite negative electrode processing equipment S-8665NC | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Graphite turning composite processing center Graphite electrode processing by CNC lathe S-1350G | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Graphite small parts CNC milling machine Processing copper graphite equipment S-750NCM | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Washing graphite for engraving machine Milling graphite machine S-310NC | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Graphite electrode blanking processing machine Graphite electrode milling machine S-1680G | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Lathes for processing graphite Gantry high-speed graphite machine S-310NC | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Graphite parts processing Center Graphite parts processing Center S-640V | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Graphite machining and CNC milling Graphite machining and CNC milling S-960V | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| CNC equipment for processing graphite electrodes CNC equipment for processing graphite electrodes S-1350G | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Graphite nut processing equipment Graphite nut processing equipment S-1680G | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Equipment for processing graphite Graphite processing center equipment S-500V | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Graphite processing center equipment Equipment for processing graphite S-1350G | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Graphite mold cnc Graphite mold cnc S-500NCM | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| CNC machining center CNC machining center S-2500G | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Graphite ring processing equipment Small milling machines for processing graphite S-310NC | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Graphite processing custom-made machines and equipment S-8665NC | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Graphite electrode equipment Graphite electrode equipment S-6550NCM | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Equipment for processing graphite molds Dry graphite precision engraving machine S-1000G | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Dry graphite precision engraving machine Equipment for processing graphite molds S-1800G | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Nano graphite processing center Multi-axis graphite CNC milling machine S-1350G | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Multi-axis graphite CNC milling machine Nano graphite processing center S-1350G | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Graphite electrode connection processing lathe Graphite electrode connection processing lathe S-1680G | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Graphite machine Graphite machine S-8665NC | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Graphite machine processing center Graphite mold CNC lathe S-1800G | Graphite machine tools, high-speed machines, graphite lathes, graphite milling machines and a series,Graphite milling machine,Graphite machine,Graphite Lathe,cnc machine,Graphite Machining Centers,three-axis graphite machine,Graphite Vertical Mills | Machine-tool building | |

| Universal Lathe ST16k20 Series | The machines are modern versions of 16k20 and 16k25 machines and can be used in various industries for various machining operations and various materials: outer and inner diameter of processing; external, internal, metric, inch, modular, worm tapping; drilling, boring. The strong structure of the casting of the bed and its precision hardened-ground zippers provide professionals in the processing, stable and reliable performance. Due to the high precision: shafts, bearings, drive shaft housing and set, the machine is particularly rigid. This allows heavy-duty handling to take full advantage of the engine's power. The machines are manufactured using advanced technology, easy to operate and to maintain accuracy over a long period of time. Hardened and precision ground worm gear main spindle to improve productivity; ensure quiet operation and long service life of the machine and smooth gear shifting. Metallurgy factories, shops, repairs and large plants | Machine-tool building | |

| Drilling rig SBSH 250 MNA-32 | Machine-tool building | ||

| Drilling rig SBSh 270 | Machine-tool building | ||

| roar GIT 700K | Machine-tool building | ||

| Drilling rig SBSh 250D | Machine-tool building | ||

| Drilling rig SBSH 160D | Machine-tool building | ||

| Mine car VS-30 | Machine-tool building | ||

| Mine car 5VS 15M | Machine-tool building | ||

| Mine car 5VS 15M | Machine-tool building | ||

| Roar GIL-52L | Machine-tool building | ||

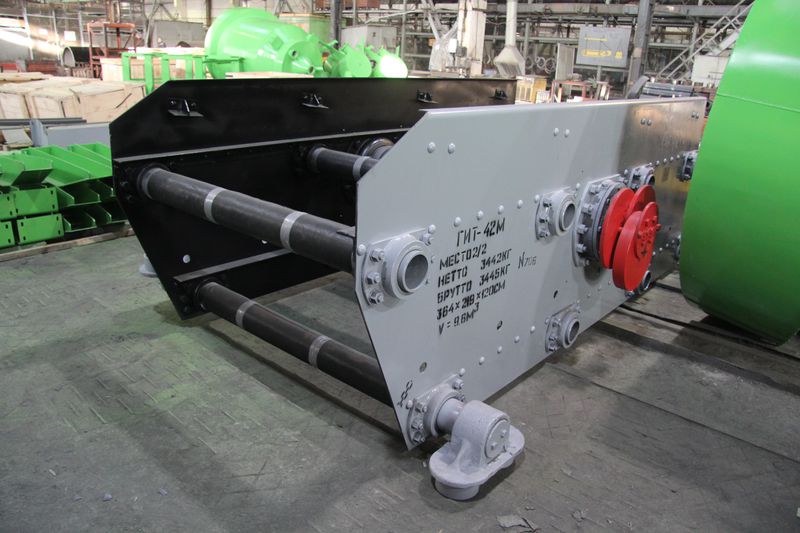

| roar GIT-42M | Machine-tool building | ||

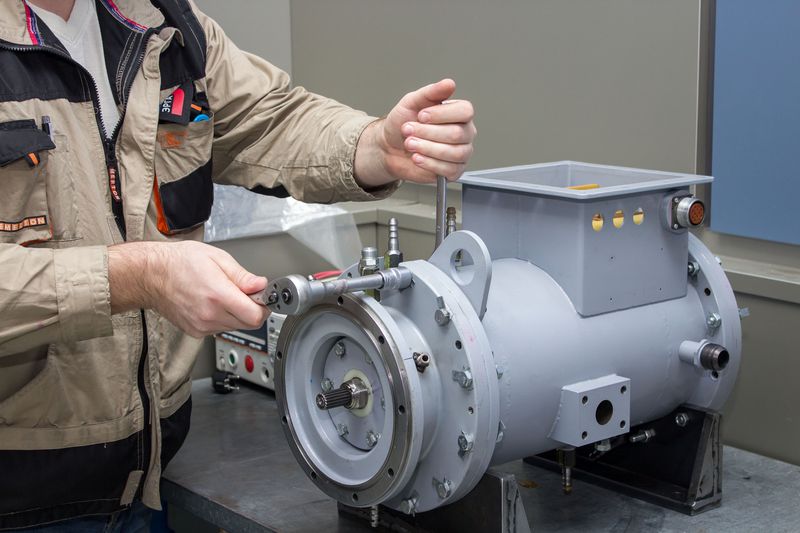

| Repair of the active part of electric motors and permanent magnet generators | In the event of a product failure, according to the results of diagnostics, highly qualified specialists of the company determine and agree with the customer the amount of necessary repair work and a list of elements to be replaced. Diagnostics is carried out in accordance with the most modern methods, using high-precision equipment. The main work, which involves the repair of high-speed electric machines of alternating current: -Diagnostics of an electric machine; -Replacement or restoration of permanent magnet rotors; -Balancing of magnetic rotors; -Diagnostics and replacement of bearings ; -Manufacture of the stator winding; -Testing of repaired equipment. The presence of a research laboratory allows the company not only to upgrade the model range of its own production, but also to carry out high-quality repair work of expensive high-speed foreign-made generators at optimal prices. Each repaired product is tested for all basic parameters for compliance with the accepted norms, standards and technical conditions. Service specialists on your call provide professional support to resolve issues of any level quickly, efficiently and on time. The professionalism of our employees is supported by the constant improvement of their level of training. The company VELMA is located in a convenient location in terms of transport accessibility and is always ready to accept products from remote regions for repair and service work. | Machine-tool building | |

| Development of magnetic systems for permanent magnet electric motors and generators. Permanent magnet rotors. | The specialists of the VELMA company have developed a unique technology for the production of these complex science-intensive products. The main differences between VELMA magnetic rotors and conventional rotors are the use of magnetic systems based on rare-earth magnets and the use of tires made of various materials – superalloys, titanium alloys and composite materials. The permanent magnet rotor does not have an excitation winding, the rotor poles are set by the orientation of the permanent magnets. The company VELMA produces rotors based on permanent high-energy magnets to order, taking into account the specific features of specific tasks and additional requirements of customers. Rotors based on permanent magnets and magnetoplastics have a number of advantages over similar products: due to the use of permanent magnets, the developed and manufactured products have high performance properties ; the ability to operate in the most severe operating conditions: at elevated temperatures, in a chemically aggressive environment and even in vacuum; the use of permanent magnet rotors allows to simplify the design of motors and reduce the noise generated by them; the use of permanent magnet rotors allows to reduce energy consumption and ensure high performance by efficiency. | Machine-tool building | |

| UNIVERSAL CLEANER "FLUORA-A" | They are polymers with performance advantages that have long distinguished Epilam® from competing surfactant technologies such as hydrocarbon and alkali. It is not flammable. PROPERTIES • No strong smell of solvent • After cleaning, the surface becomes resistant to dirt. • Cleans and degreases. , by wetting, by roller • Low consumption of the composition • The calculated amount of the composition is determined empirically MODIFICATIONS: FLUORA A1 – QUICK EVAPORATING cleaner FLUORA A2 – OPENING cleaner FLUORA A3 – PAINTS cleaner (does not leave a film, for the coating of the chamber – FLUORA 6 UREVALIUM A4 and COLORS A4 – PAINTED SURFACES OF FLUORA A7 – CORROSION cleaner FLUORA A8 – PLASTIC and FLUORA A9 COMPOSITES – ALCOHOL substitute (antiseptic) FLUORA A10 – OILS cleaner, flotator FLUORA A11 – SULFUR cleaner, catalyst TECHNOLOGY A12, water systems specifications TECHNICAL CHARACTERISTICS – Field of application: all areas of industry – Action: some modifications create a thin protective coating, which can significantly reduce the coefficient of adhesion (sticking). – Density at t = 20 ° C: 0.8-1.3 g / cm³ – Consumption rate 1 l: 7 … 10 sq. m. (on average) – Waiting time before cleaning: up to 5 minutes – Application temperature: -40 ° С … + 50 ° С | Machine-tool building | |

| Screw-cutting lathe AB250ES.01 | Due to the wide range of tasks to be solved, lathes of model 250 belong to the advanced technological equipment that allows the production of parts of various shapes and complexity in the interests of all industries. only inch and metric, but also modular). For this reason, it is actively used at enterprises precisely for performing such work. The screw-cutting lathe 250 ABEC T.01 is a universal equipment on which, in addition to turning, it is possible to carry out various types of work, such as: turning the outer cylindrical surfaces; turning the outer conical surfaces; processing ends and ledges; cutting grooves and cutting off parts; boring holes (cylindrical and conical); drilling, countersinking and reaming holes; cutting external and internal threads with a cutter, tap and die; shaped turning; rolling of corrugated surfaces. Those. specifications Maximum length of the workpiece, mm 500 Maximum diameter of the workpiece to be processed, mm: over the bed 240 over the slide 168 Maximum diameter of the bar processed in the chuck, mm 24 Maximum cutter section, mm 16×16 End of the spindle according to GOST 12593-93, 4 Size of the inner cone of the spindle, Morse 4 Size of the inner cone of the pin tailstock, Morse 3 Quill travel, mm 85 Spindle speed, min-1 50-2500 Longitudinal feed, mm / rev 0.01-1.8 Transverse feed, mm / rev 0.005-0.9 Lead of the cut metric thread, mm 0.2-48 modular, modules 0.2-12 inches, threads per 1 '' 24-0.5 Power of the main drive, kW 3 Accuracy class according to GOST 8-82 V, high Roughness of the product sample, μm 0.63 Overall dimensions, mm, no more than length 1790 width 810 height 1400 Weight, kg, no more than 1180 | Machine-tool building | |

| Guillotine shears for metal NGM-13 (analogs: NL3421, NA3221, NA3121, NG-13, NK3421N) | The largest thickness of the cut sheet with a temporary resistance of 500 MPa, 13 mm Width of the cut sheets, 2000 mm Size of the cut angle, 63x63x6 mm Diameter of the cut bar, mm no more than 30 mm Tech. specifications Knife stroke. mm 92 mm Clamping force, not less than 29 kN Length of sheet cut with a stop, no more than 500 mm Power of the electric motor, 18.5 kW Cutting angle at the side stop 900, 450 Operating mode single cycle, automatic cycle Manual, pedal control Overall dimensions of scissors НГ-13, mm Length 3100 Width 2000 Height 2250 Equipment weight, kg 5600 | Machine-tool building | |

| Guillotine shears for metal НГМ-6,3 (analogues Н478, Н3118, НГ-6,3) | The largest thickness of the cut sheet with a temporary resistance of no more than 500 MPa 6.3 mm Width of the cut sheets, no more than 2000 mm Size of the cut angle, no more 56x56x5 mm Diameter of the cut bar, no more than 30 mm Tech. specifications Knife stroke 92 mm Clamping force, not less than 18 kN Maximum length of the cut strip when working with the back stop 500 mm Electric motor power, not more than 11 kW Cutting angle on the side stop 900, 450 Operating mode single cycle, automatic cycle Manual, pedal control Overall dimensions of the scissors НГМ-6,3 , no more Length 3050 mm Width 1200 mm Height 1565 mm Equipment weight, no more than 3550 kg | Machine-tool building |