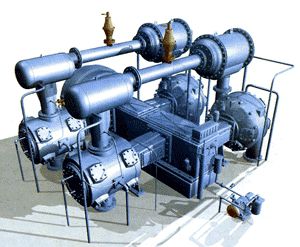

Installation for welding in a controlled environment Model USKS-27

Price from: $ 1

The USKS-27 unit is designed for automatic and manual arc welding with a non-consumable electrode in a controlled environment of circular and longitudinal seams of products made of chemically active metals and alloys based on them, installed on the rotator faceplate, with or without filler wire. The maximum diameter of the welded products is 800 mm, maximum height – 800 mm, maximum weight of the welded product – 250 kg The installation allows automatic welding with a welding head of butt, tee, overlap joints of bodies of revolution with a horizontal axis of rotation at various positions of the head – from vertical to rotated at an angle of ± 45 ° from vertical. When the axis of rotation is set to a vertical position, it is possible to weld the end connections of the bodies of revolution with the vertical position of the head. The installation can be used to weld with manual welding torches for 150 A and 400 A to body parts of bends, fittings, plates, brackets, etc. In automatic mode, welding of all joints can be carried out with or without oscillation of the electrode. Welding of butt joints can be carried out with automatic maintenance of a given value of the arc gap. The USKS-27 installation is a chamber installation consisting of complexes: mechanical, vacuum, power, automatic control systems, air supply systems, cooling systems. the chamber cover, the item to be welded with accessories on the faceplate of the rotator and a mechanized welding head, two hand torches for 150 A and 400 A.

Send Me Quotation

The function is avialable for logged in users only

Specification

| Product value | -3 м3 |

| Product length | 1 м |

| Product width | 1 м |

| Product height | -3 м |

Reviews

There are no reviews yet.